The Statfjord B platform

Giving the platform four shafts meant the topside could have a larger area than Statfjord A. Its buoyancy at tow-out was high enough for all topside facilities, including the quarters, processing equipment and drilling module, to be installed inshore. Another benefit of the bigger area was that the living quarters could be physically separated from the drilling and production zones. Statfjord B began production on 5 November 1982, when it ranked as the world’s largest concrete platform and the first four-shaft Condeep.

The concrete structure comprises 24 cells, with 19 used to hold crude oil, one for storing diesel oil, and four extended into shafts to support the topside. Two shafts are used for drilling, one for utilities and the fourth for risers. In addition to a latticework module support frame (MSF), the topside is built up of modules installed on three levels – the cellar, module and weather decks. A single point mooring buoy (B-SPM) was tied back to Statfjord B for offshore loading of crude from 1982 to 1990. This was then replaced by an Ugland-Kongsberg offshore loading system (Ukols), designated OLS-B.

Drilling rig

B-plattformen,

B-plattformen,The rig comprises a derrick installed on skids running between the northern and southern drilling shafts. Positioning the derrick over a wellhead is accomplished with hydraulic jacks, and the unit can be moved both east/west and north/south.

Topside

The topside measures 114 metres long by 55 wide, providing a surface area of 6 270 square metres and total deck space of 28 900 square metres. It comprises the cellar, module, weather and upper weather decks.

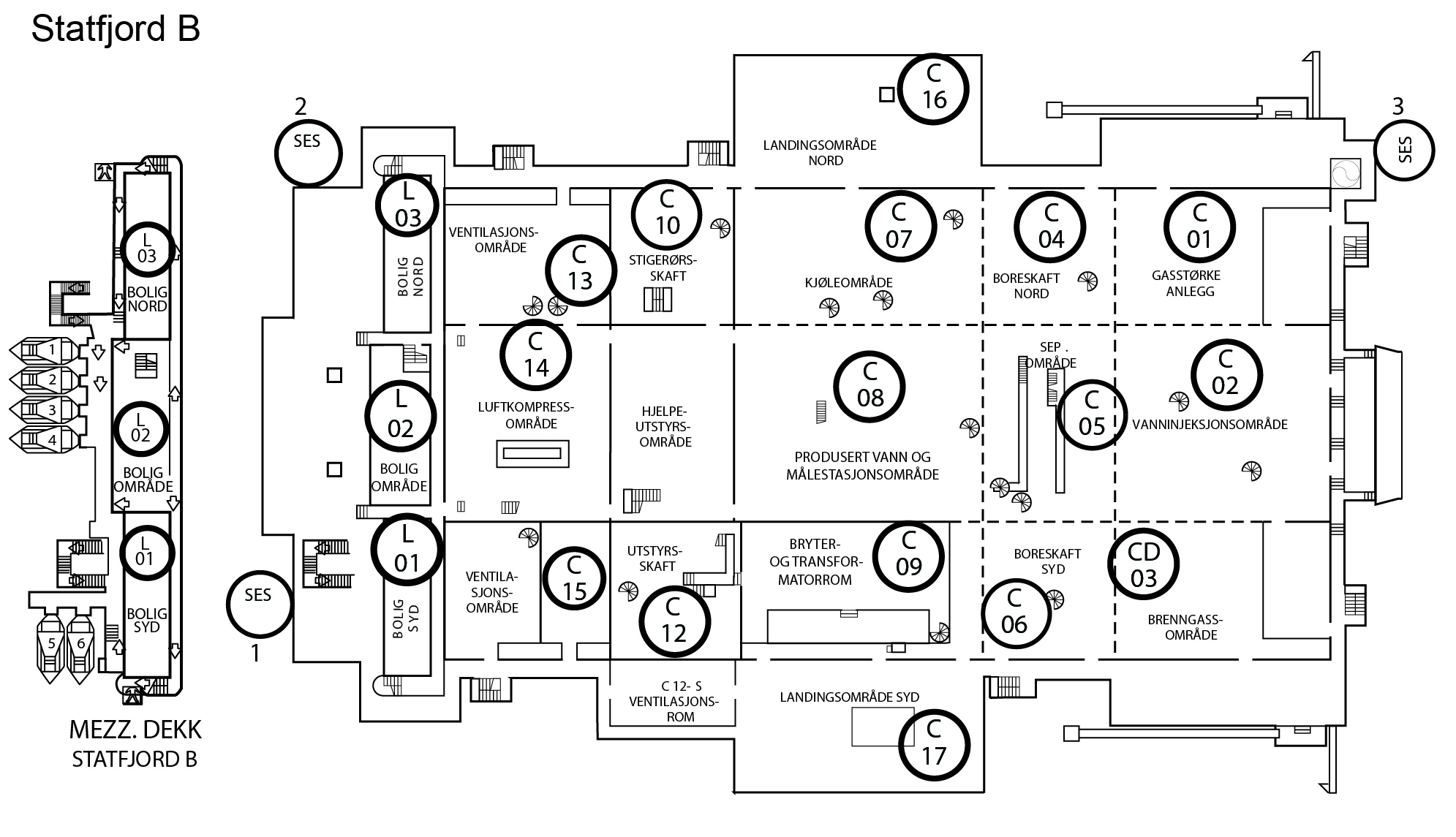

Cellar deck

B-plattformen,

B-plattformen,The cellar deck comprises the whole interior of the robust MSF and encompasses facilities at its eastern end for gas treatment and metering of exported oil and gas. Large areas also hold ventilation equipment covering the whole platform. Virtually no partitions are found on the cellar deck in order to ensure natural ventilation. However, the actual gas treatment area in the eastern end is separated off by a powerful firewall. The main control room stands centrally in the western part at mezzanine-deck level, and is directly connected with the middle quarters module.

B-plattformen,

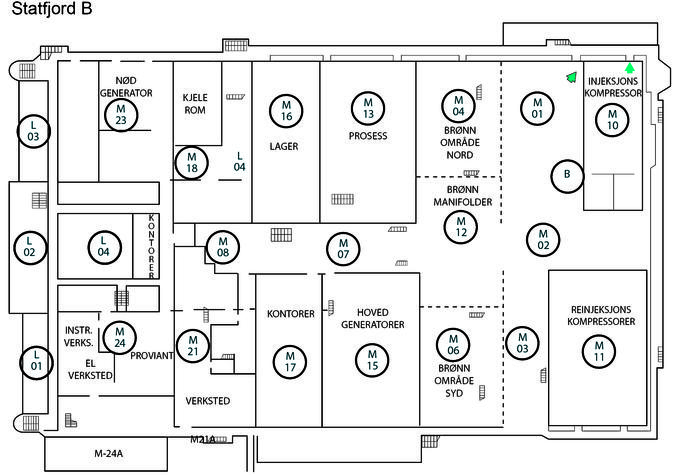

B-plattformen,Module deck

This comprises 13 separate modules. At the eastern end are the drilling unit and the main process plant. The utilities are located on the western side, separate from the process facilities.

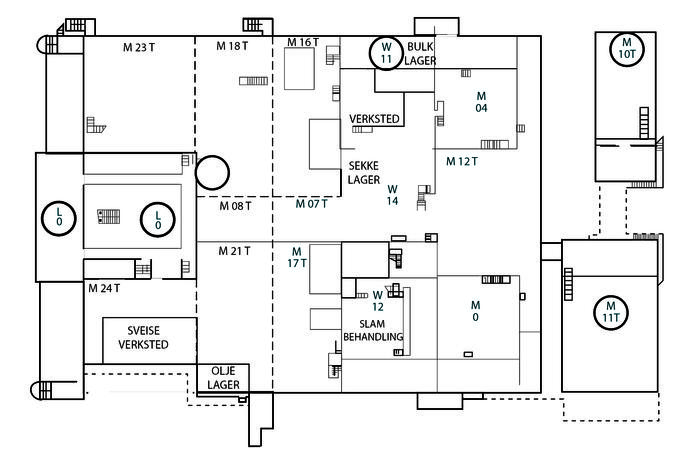

Weather deck

B-plattformen,

B-plattformen,This area largely comprises the tops of the modules making up the deck below. It also contains its own module for storage of drilling equipment. These large open areas are used for storage and for positioning equipment being loaded from or discharged to supply ships.

B-plattformen,

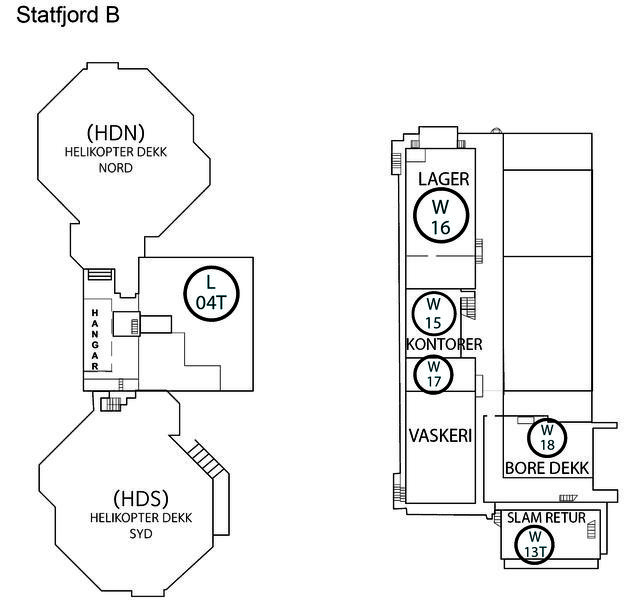

B-plattformen,Upper weather deck

This comprises the helideck and the top of the drilling equipment module. The southern helideck was installed after the platform had been in operation for a while, because of problems during helicopter landing and take-off.

Living quarter modules

Comprising three modules, the living quarters are positioned on three large beams projecting from the base of the MSF. It extends in height from cellar deck to upper weather deck. The big flare boom is also attached to the MSF, as far as possible from the living quarters. All lifeboat stations are positioned on the outside of the MSF, most of them west of the quarters.