The Statfjord C platform

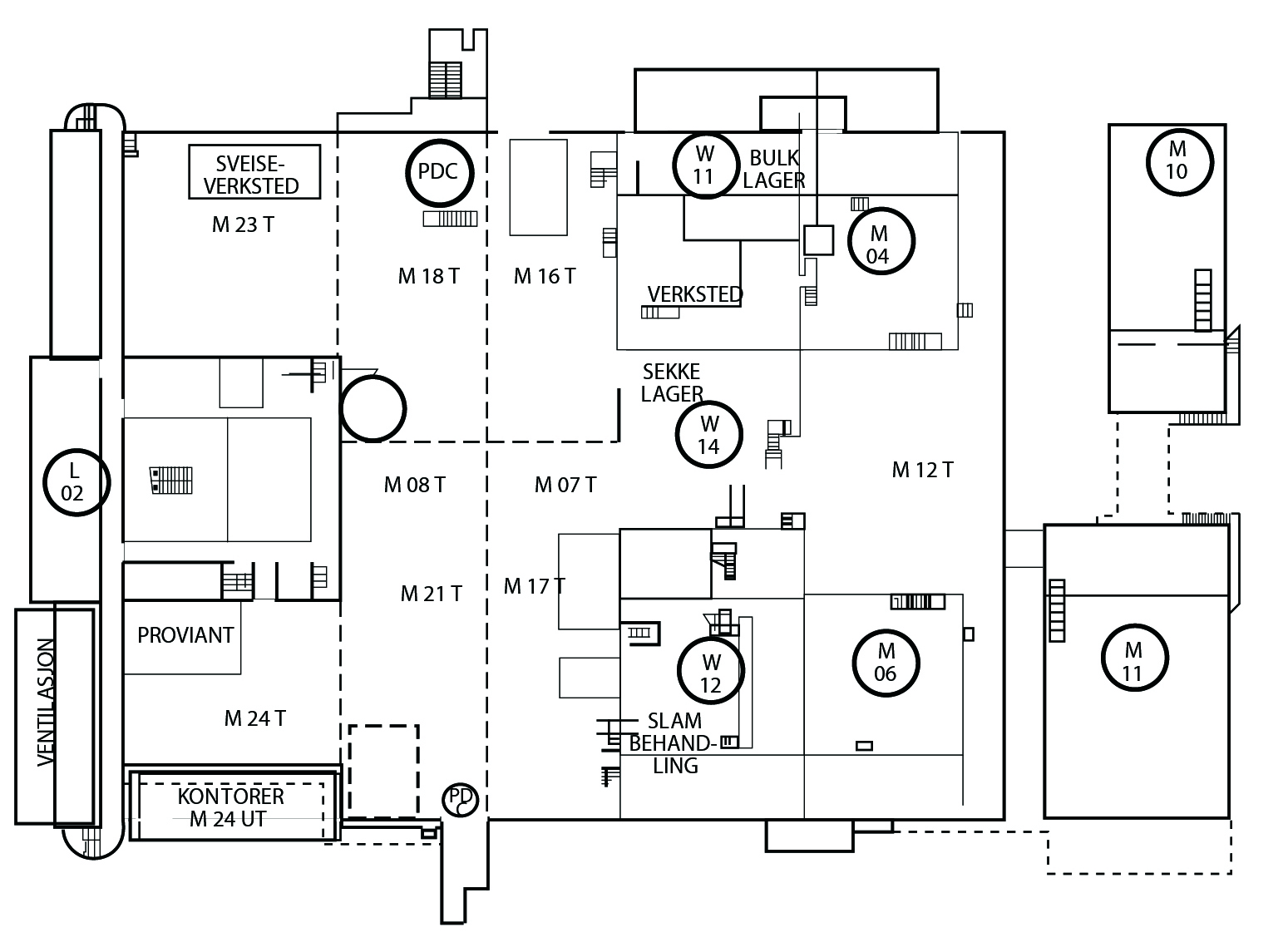

Statfjord C is an integrated platform standing 5.5 kilometres north of Statfjord A. Built as a virtual copy of Statfjord B, it rests on a Condeep concrete gravity base structure (GBS) with four shafts. It began production on 2 July 1985.

More about statfjord b

close

Close

C-plattformen,

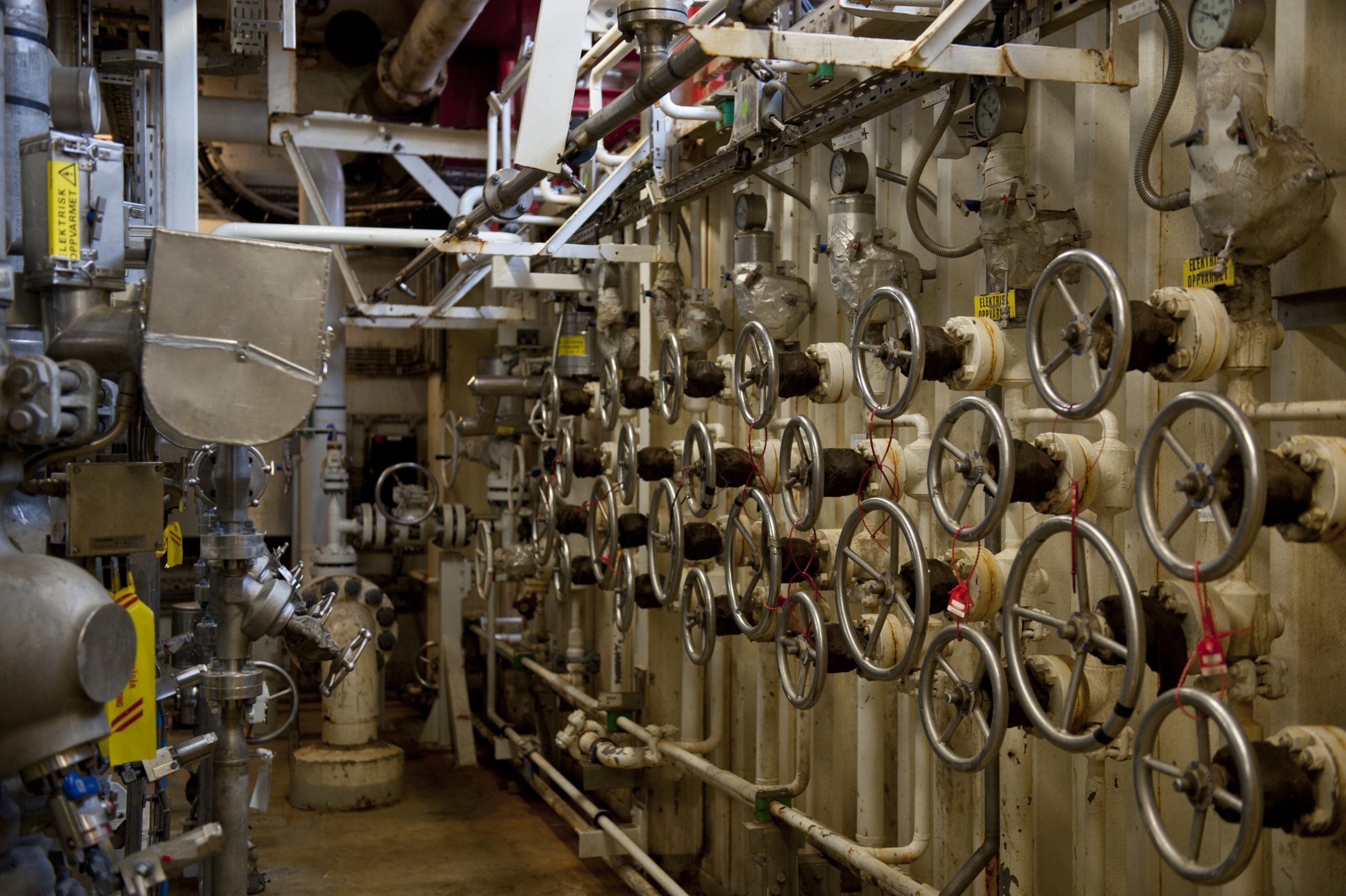

C-plattformen, hjelpesystemer, jet fuel, engelsk, C-plattformen

hjelpesystemer, jet fuel, engelsk, C-plattformen Statfjord C, engelsk, bygging,

Statfjord C, engelsk, bygging, C-plattformen,

C-plattformen, c-plattformen,

c-plattformen, Statfjord C, bygging, engelsk,

Statfjord C, bygging, engelsk,