Social History in the Offshore Industry

The modern history of petroleum began in the United States in the 1850s, but it was not until the twentieth century that the world was completely transformed by oil. This highly usable energy source provided heat and power and revolutionized the transport of goods and people. Increasing demand turned the search for and production of oil into a global industry. However, although exploration and production were started onshore, it was soon found that oil and gas fields stretched out into the sea. The extension into the offshore fields introduced a new range of technological challenges. It also gave the life of the oil worker a new dimension. Oil exploration and production offshore started in the Gulf of Mexico after World War II. Later, the offshore industry also developed off the coasts of Africa, South America, Alaska, China, and Australia, and in the North Sea. This article on social history in the offshore industry draws mainly from experiences from the North Sea.

Arbeidsliv på Statfjord, forsidebilde,

Arbeidsliv på Statfjord, forsidebilde,Oil workers offshore have a unique working environment. They spend twenty-four hours a day at their place of work when out on the rigs. Their surroundings are a steel or concrete construction—a factory—isolated far out in the ocean. Their working hours are often twelve hours on and twelve hours off. After about fourteen days offshore, the oil worker returns to land by helicopter for a rest period. Because of the distance involved and the shift nature of the work, the periods offshore and the periods back on land are two distinct worlds, both physically and mentally.

Borevæskestreiken,

Borevæskestreiken,The working environment offshore consists of several working cultures, depending on the tasks to be carried out and the personnel involved. There are dividing lines in culture between drilling and production—between migrant and stationary work.

In order to find oil, exploratory drillings must be carried out. These are made from movable rigs at places where the company with the concession has permission to search. The drilling crew can be compared to construction workers who follow work from site to site. Those leading the drilling stage are usually experts employed by the operating company. When oil exploration began in the North Sea in the middle of the 1960s, this exploratory drilling was led by American drilling experts. Europeans were initially employed only as assisting personnel. The requisite qualifications were youth, health, a basic grasp of English, and a can-do attitude. Formal qualifications were not necessary. The work processes were taught through on-the-job training so that the rhythm of the work could be felt first-hand. Social interaction in this environment was direct and the vocabulary was rough. A worker could rise in the ranks from roustabout to roughneck, tool pusher, derrick man, crane driver, and finally driller. Over time, Europeans developed the necessary technical and theoretical competence to take over managerial roles. Educational institutions were eventually able to offer necessary petroleum-related theoretical education. Engineers and other highly educated people qualified into managerial roles, and in the 1980s the nationalization process in European countries was nearing completion.

Arbeidsliv på Statfjord,

Arbeidsliv på Statfjord,Drillers are still needed when oil has been found and a field starts production. They drill production wells, and in some cases they drill water- or gas-injection wells. However, the central players in this new phase are those dealing with production. Their task is to ensure that oil and gas flow as steadily as possible from the wells, and they use parameters such as pressure and temperature to control the output. Crude oil is separated so that oil and gas are extracted separately and water is removed. A certain theoretical background is necessary to carry out these processes, as are skills of precision and attentiveness. The work is comparable to that of work at an onshore refinery. When the fields in the North Sea sector started production, many refinery employees from the United States were brought in to lead the work. Jobs in production are stable and secure in that each field generally has continuous production over several years. Social interaction in this part of the process is more civilized than it is at the drilling stage. Production staff is employed by the operating company, while assisting staff is employed by contracting companies.

catering,

catering,The most important support functions on a production platform are well maintenance and other maintenance, catering, cleaning, and health. In addition to this, supply services bring goods by boat and bring personnel by helicopter. Underwater operations are necessary to monitor and maintain underwater installations and pipelines. Because of factors such as helicopter transport and the need for accommodation and food to be provided, the cost of an individual worker offshore is seven to ten times that of a worker onshore. Computer technology and remote control are key concepts for bringing these costs down in the future, because computer technology enables more operations to be controlled from land. Newer fields employ pure underwater solutions in which all processes are controlled from land. Moving more functions to land also reduces risks: a production platform is like a huge gas stove, and an accident can have fatal consequences. Of course a great deal of effort is made to prevent accidents.

All oil companies have had to take tough measures when oil prices have been low, including cutting staff to save costs. Trade unions have had a role to play here. Traditionally trade unions were concerned with securing the rights of oil workers as regards pay, employment conditions, and so on. The unions were also forerunners in ensuring safety at work. Increasingly, as the oil industry has matured and the average age of oil workers has risen, welfare issues including issues of health have come into focus.

Bedriftshelsetjenesten i et historisk perspektiv,

Bedriftshelsetjenesten i et historisk perspektiv,Women were completely absent from offshore oil installations for a long time. In most Asian countries, women are still prohibited from even visiting oil installations. But since the end of the 1970s, emphasis has been placed on enabling women to work offshore, at least in the United States and Norway. The first women involved in offshore work were often employed in catering or as nurses, but female engineers were also employed. Now most gender boundaries have been broken down, and women can also be found in traditionally male jobs—as drill-floor workers, for instance. Physically demanding work has largely been taken over by machinery. Still, only about 10 percent of the workers in the Norwegian sector are women, and this percentage is still significantly greater than that in, for instance, the British sector, where only 1 percent of the workers are women.

støping av a-en,

støping av a-en,

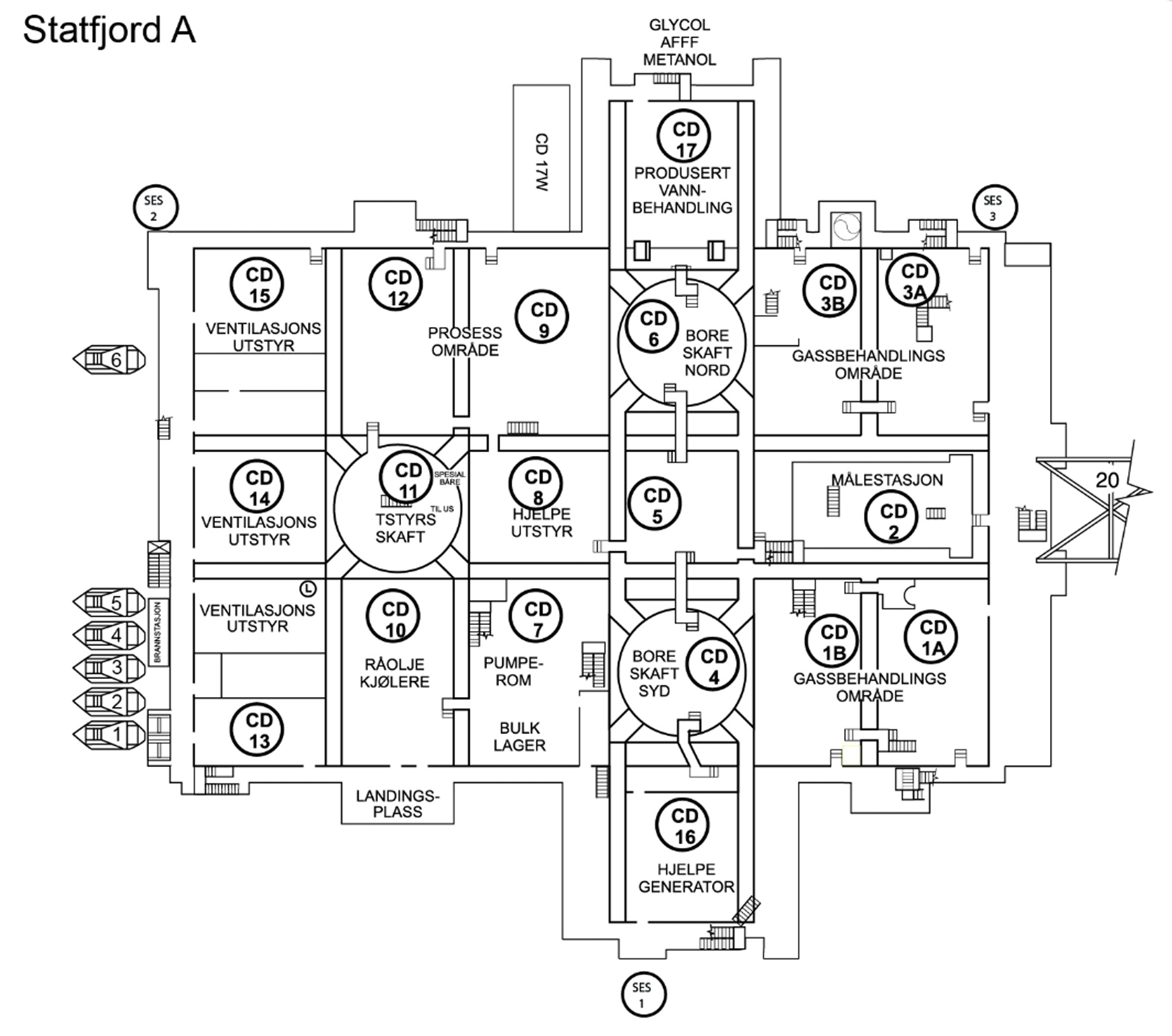

Statfjord A,

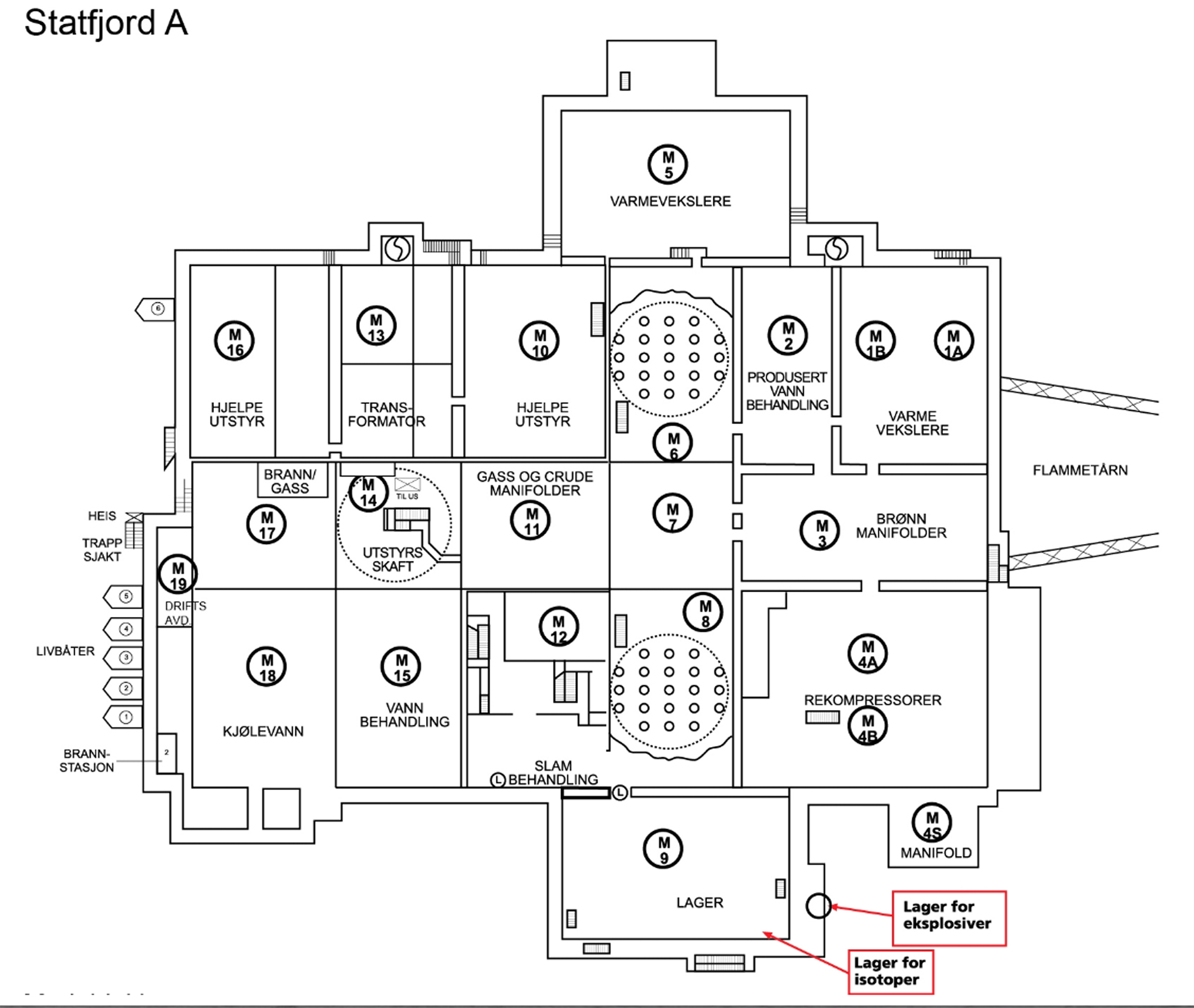

Statfjord A, Statfjord A,

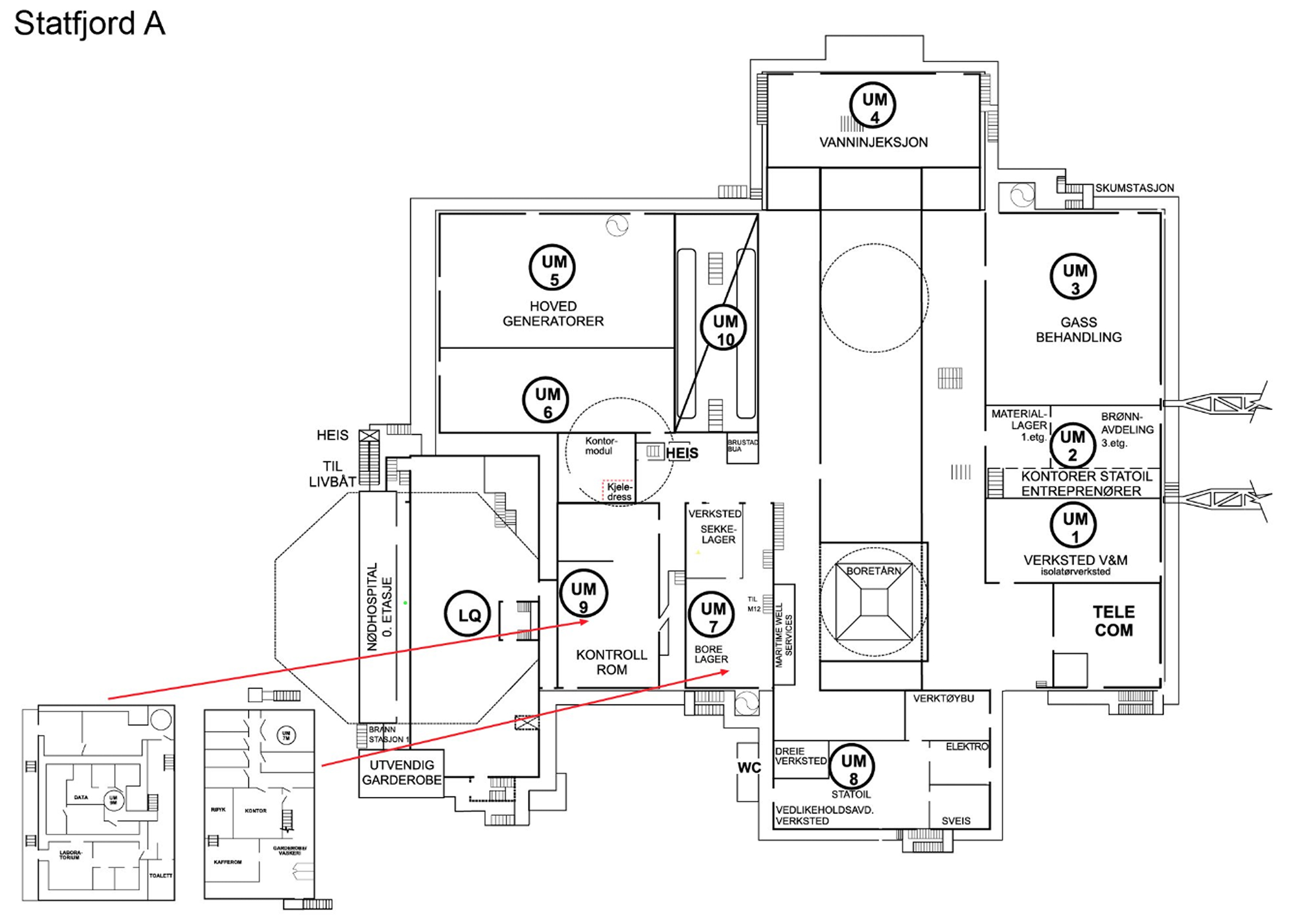

Statfjord A, Statfjord A,

Statfjord A, Bygging av A-dekket,

Bygging av A-dekket, støping av a-en,

støping av a-en, Statfjord A,

Statfjord A, Statfjord A,

Statfjord A,