Geology and reservoir

Kilder:

Main considerations in develoment of Statfjord Field, H. Ager-Hansen, Statoil and J. Medley, Mobil

Statfjord Field: Field and Reservoir Management Perspectives, Atle Aadland, Olav Dyrnes and S.R. Olsen, SPE and O.M. Drønen, Statoil A/S. SPE Reservoir Engineering , August 1994

Increasing economic recovery by synergetic development of neighbouring fields in the Norwegian Continental Shelf. Adolfo Henriquez, Øystein Arvid Håland, Stein Børre Torp (Statoil) 2001

Turning a North Sea Oil Giant into a Gas Field – Depressurization of the Statfjord Field, R. Boge, SPE, S.K.Lien, A. Gjesdal and A.G. Hansen, SPE, Statoil. SPE 96403 2005

The use of sea water tracer as a tool for history matching of the Statfjord Fm simulation Model. Master Thesis, Henriette Strøm, 2010

Triassic lithostratigraphy of the Northern North Sea Basin. Kjell-Sigve Lervik – Norwegian Journal of Geology 2006

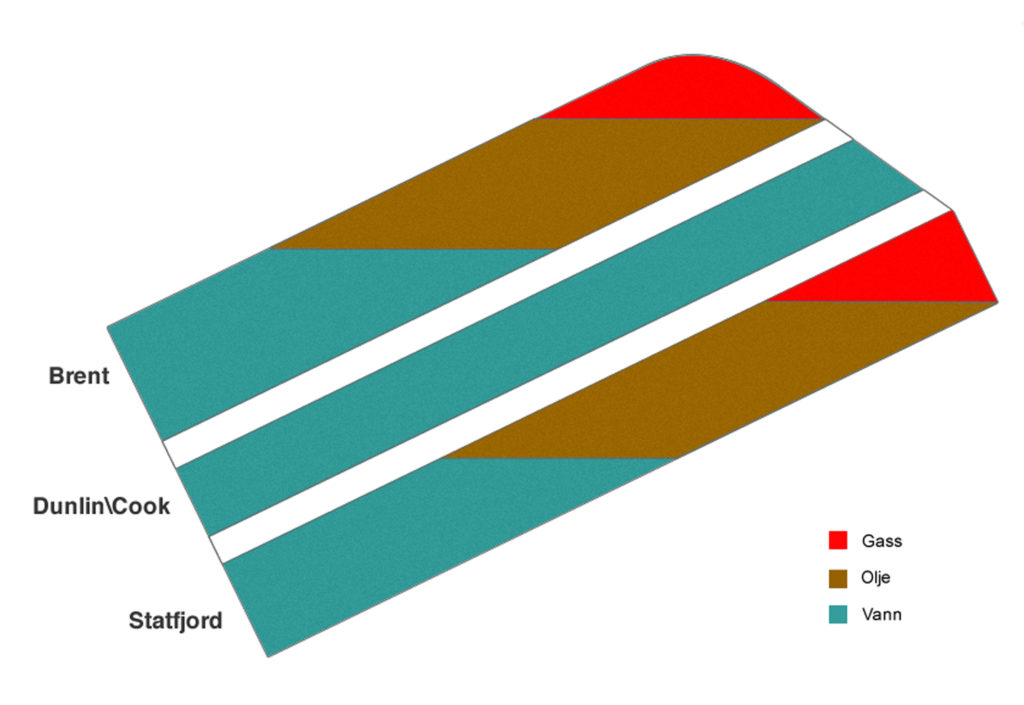

geologi og reservoar, illustrasjon

geologi og reservoar, illustrasjon