Statfjord subsea

støping av a-en,

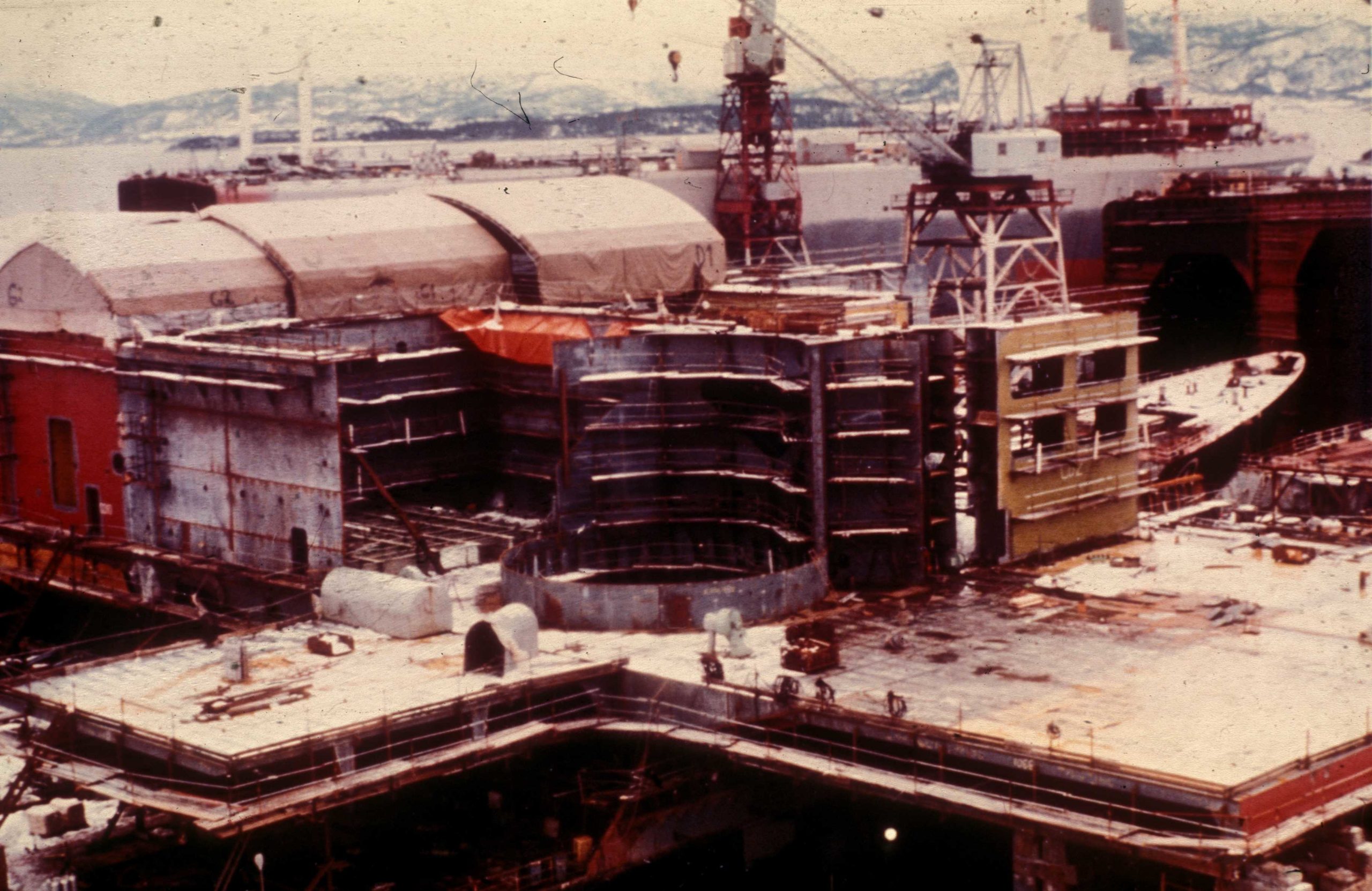

støping av a-en,Built by Norwegian Contractors at Hinnavågen in Stavanger, the GBS comprises 19 cells arranged in a concentric formation. Most of these are used for oil storage. Three have been extended upwards as shafts to carry the topside. The platform, which measures 254 metres in height from the seabed to the top of the drilling derrick, was towed to the field in 1977 and came on stream in November 1979.

Oil was exported via a loading buoy located a few hundred metres away. The original articulated loading platform (ALP) was later replaced by a specially developed Ugland-Kongsberg offshore loading system (Ukols).

The rig comprises a derrick, modules for such functions as mud mixing, and pipe storage. Wells are drilled through two of the concrete shafts supporting the topside. A total of 42 slots are provided. Both production and gas/water injection wells have been drilled, with an average depth of 2 500-2 800 metres. The derrick stands on skids which allow it to be positioned over the various wells with the aid of hydraulic jacks.

The topside measures 86.2 metres long by 83.6 wide, providing a surface area of 5 000 square metres and total deck space of 21 000 square metres. Total height to the helideck is 43.2 metres, while the base is 28 metres above the sea at its lowest point.

Statfjord A,

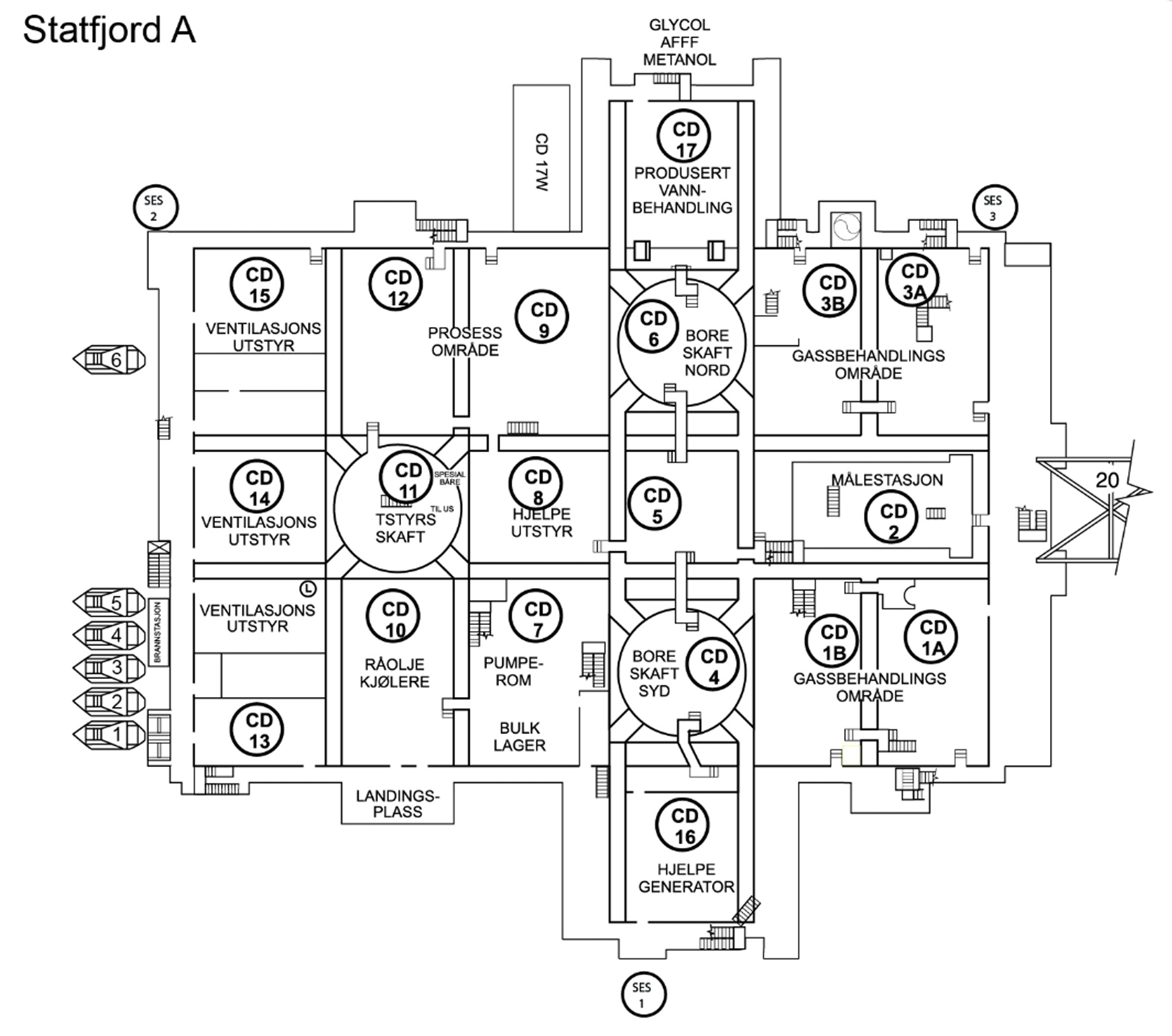

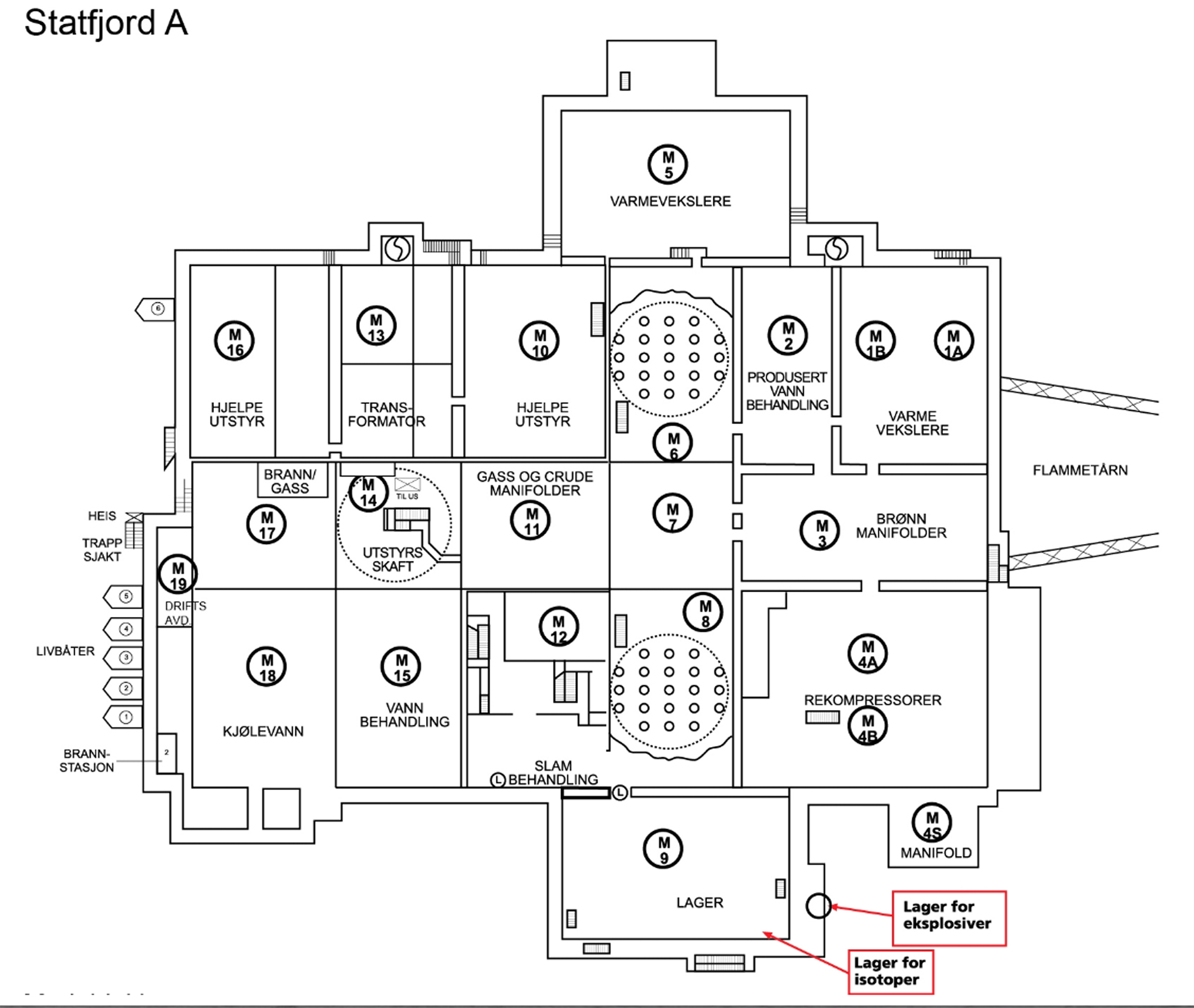

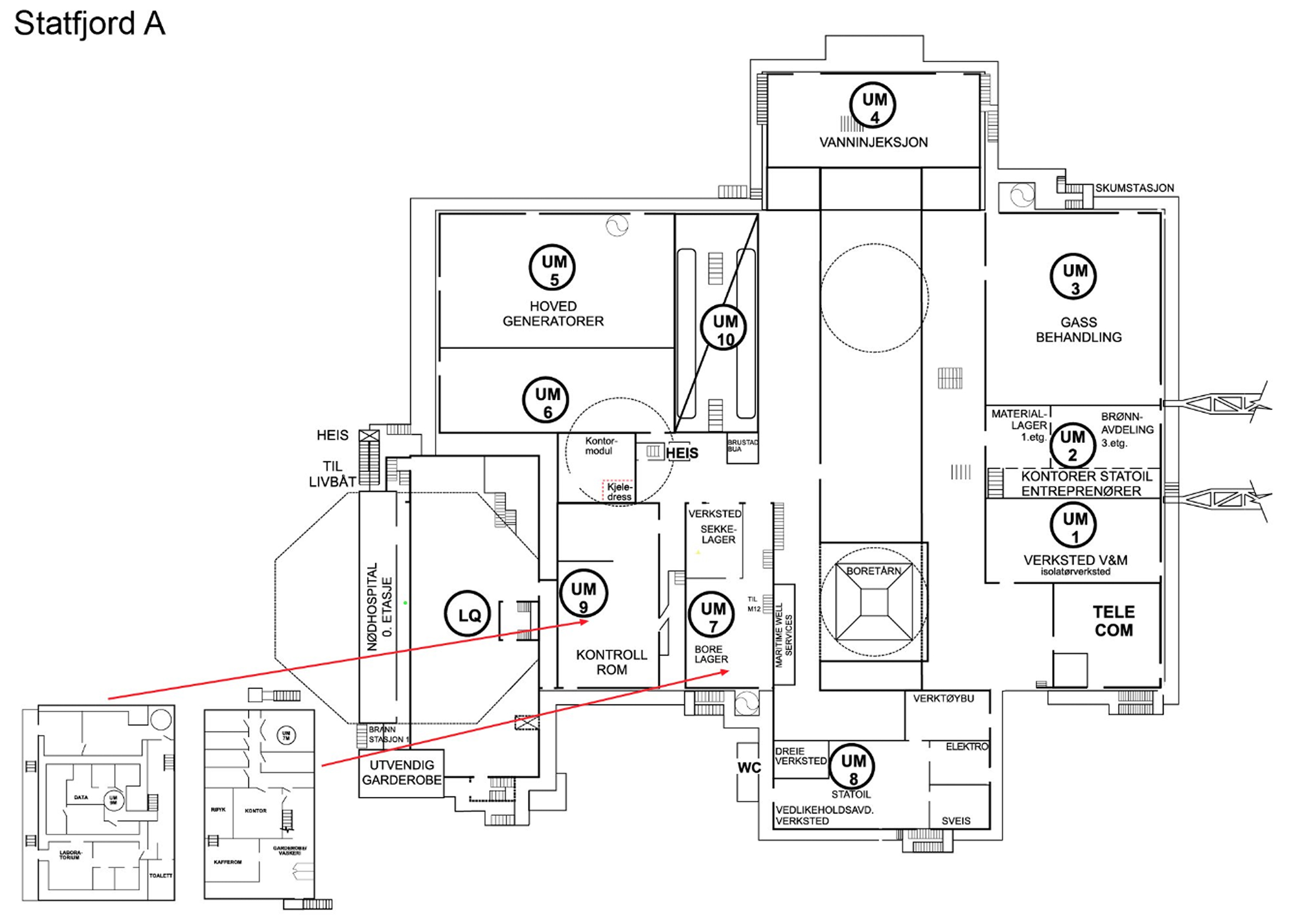

Statfjord A,The lowest of the steel decks, the cellar deck is built into the module support frame (MSF) which carries the rest of the superstructure. Divided into individual sections with double bulkheads, it forms an integrated steel structure. The flare boom extends for 116 metres at an angle of 45 degrees from its eastern end to burn off all associated gas for brief periods.

Statfjord A,

Statfjord A,Located above the cellar deck, this has acquired its name because it is partly composed of prefabricated modules. The south-western corner, with the M11, M12, M14,M15, M17 and M18 units, forms part of the cellar deck’s integrated steel structure.

With the exception of UM7, this deck is built up entirely of modules and lies immediately above the module deck. UM7, which is part of the drilling module, has been constructed as an integrated steel structure together with the cellar deck and the south-western part of the module deck.

Statfjord A,

Statfjord A, Bygging av A-dekket,

Bygging av A-dekket,The living quarters provide 100 cabins. These were originally two-berth but converted for single occupancy in 2000-2003. The six-storey structure comprises three modules. A partial seventh floor is provided by the helideck, radio shack and helicopter fuel tanks. The marine control centre was positioned there in the early years, but later moved to Bergen. In addition to the cabins come a canteen and recreation rooms. A lift and internal staircase connect the floors, while external staircases serve as emergency exits. The illustration shows the layout of a typical cabin in the living quarters.

The tops of the uppermost modules form the weather deck. This area is used for storage and for loading/discharging cargo by the large platform cranes.

støping av a-en,

støping av a-en,The lower section of the GBS comprises 19 concrete cells. Sixteen of these are used for storage, while three extend upwards to form the shafts supporting the topside.

With an internal diameter of 19 metres and a height of 67 metres, the storage cells are individual concrete cylinders which each have a capacity of 80 000 barrels.

Fifteen of the cells are used to store crude oil, and can collectively hold about 1.2 million barrels. Cell 6 is equipped with an internal cylindrical tank to store up to 21 750 barrels of diesel oil. The annulus between the internal cylinder and the cell wall provides 63 500 barrels of storage space for the oil-water emulsion (sludge) which forms during platform operation. All 16 of the cells are partly filled with sand ballast covered by a concrete lid. They are kept filled with liquid at all times. When oil is exported, the cells take in water to maintain their liquid content.

Statfjord A,

Statfjord A,One of the three shafts supporting the topside, this contains a series of decks carrying pumps for fire, ballast and sea water, ballast water tanks and pumps for crude oil loading.

These are completely filled with conductor tubing for a total of 16 wells in each shaft. The illustration shows the distribution between production and water/gas injection wells.

Statfjord A,

Statfjord A,

Under the letter of intent signed between Mobil and Aker, the module support frame (MSF) for Statfjord A would be fabricated at Aker Verdal with outfitting by Aker Offshore Contractors (AOC). The latter also had the contract for mechanical outfitting in the shafts of the concrete gravity base structure (GBS).

When it turned out that the topside would be larger and heavier than first agreed, the Aker Verdal yard ran into capacity problems.[REMOVE]Fotnote: Haga, T. (1993). “Stordabuen går offshore” : Arbeid og faglig politikk ved A/S Stord verft 1970-83 (Vol. 1993-4, AHS (trykt utg.)). Bergen: Gruppe for flerfaglig arbeidslivsforskning, Universitetet i Bergen: 260. Stord Verft south of Bergen, which had only built ships – primarily oil tankers – before, was hit when the tanker market collapsed in the wake of the oil crisis. An order for 11 supertankers was cancelled, leaving the yard short of work.[REMOVE]Fotnote: Grove, K., Heiret, J., & Stord jern- & metallarbeiderforening. (1996). I stål og olje : Historia om jern- og metallarbeidarane på Stord. Stord: Stord metall- og bygningsarbeider[e]s fagforening: 161. og Myklebust, A., & Aker Stord A/S. (1994). 75 år på Kjøtteinen : 1919-1994 : Jubileumsbok for Aker Stord. Stord: [Aker Stord].

Bygging av A-dekket,

Bygging av A-dekket,Aker accordingly submitted a proposal to Mobil in February 1975 to transfer the job of building the Statfjord A topside from Verdal to Stord. Mobil accepted this, and Stord Verft thereby acquired its first offshore assignment. The contract was signed on 5 April 1975.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 178.

But Stord Verft was soon to discover that fabricating offshore structures differed significantly from shipbuilding. While the latter was a form of mass production, a platform had to be custom-built.

The original contract allowed Stord Verft to take on a wider scope of work. As initially conceived, the topside was to comprise a single MSF where the equipment was installed in modular form – almost like a large Lego construction.

Bygging av A-dekket,

Bygging av A-dekket,Since the yard had spare capacity, however, Aker initiated negotiations with Mobil on a new integrated structure. Rather than all the modules forming a conventional modular system, the support structures for a number of these would be incorporated in the MSF, and their equipment then installed in them.

The contract with Aker’s Stord Verft embraced the following elements.

Design and fabrication of the steel topside, with an estimated weight of 6 800 tonnes. This included steel procurement, towing the topside to the mating site and mating with the Condeep GBS.

Design and fabrication of the MSF for the integrated M6, M8, M11, M12, M14, M17, M18 and UM7 modules and installation of the deck, with an estimated weight of 1 828 tonnes. This also included steel procurement.

Outfitting the cellar deck and the above-mentioned modules. This would be done to the extent that approved drawings, specifications, equipment and materials were available at Stord Verft.

While contract negotiations were under way between Aker and Mobil, appraisal wells being drilled on Statfjord revealed that the field was larger than originally thought. On the basis of that knowledge, it was resolved to double production capacity on the platform from 150 000 barrels per day to 300 000. In order to be able to handle such large volumes of oil, the topside facilities had to be expanded from one to two process trains. That naturally doubled the size and weight of the equipment. This in turn meant that the MSF had to be strengthened to handle the weight.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 141.

A partially integrated topside would be significantly more complicated, but Aker justified the design changes submitted to Mobil on 6 February 1975 by noting that steel weight would be reduced. Mobil accepted the revised design and a new contract was signed on 5 April 1975.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 178.

This meant a welcome increase in the scope of work for Stord Verft. A number of the modules were originally due to be fabricated at other yards and engineering works in Norway and abroad which were also struggling with the after-effects of the oil crisis. Because Stord Verft was now going to integrate these modules in the MSF, the other fabricators lost sorely needed work.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 183. Modules were built by Kværner/Sterkoder in Egersund and Kristiansund (M1A, M1B, M2, M10, M13, M16, UM8, UM9 and the toolroom), Nordland Offshore A/S in Sandnessjøen (UM9B and the telecommunications module), Bodø Mekaniske Verksted (UM2 and M10 top), Wilson Walton, Middlesbrough (M3, M5 and M9), and Curtis Wright/RSV in Rotterdam (M4A, M4B, UM5 and UM6). In addition, Norway’s Leirvik Sveis completed M9.

In retrospect, it is clear that the local management at Stord Verft took an unrealistic view of the transition from shipbuilding to platform construction. A topside for what then ranked as the world’s largest offshore installation was far more complicated, and new standards had to be met – particularly for welding.

The amount of engineering design work was greatly underestimated, and detailed design proved the first casualty. While the yard had been accustomed to using its own drawing office, it now received detailed drawings from Matthew Hall Engineering (MHE) in London. The latter had the contract for the technical design of outfitting and process equipment.

MHE had won an engineering management contract (EMC) for the Statfjord A topside (see the section on the construction contracts for more details). This job embraced conceptual and technical design, management of process equipment and modules – including procurement – award of fabrication contracts and construction site supervision.

Although the EMC had been put out to competitive tender, a tight market meant that Mobil received only two bids. The operator had been concerned from the start about MHE’s lack of experience with similar projects, but had no choice but to award it the contract if the schedule was to be maintained.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 168.

It quickly transpired that the design work failed to meet the required standard and would be delayed. MHE had estimated 400 000 hours for the work, with 90 per cent completed by the end of 1975. But the company ran into problems.

In addition to insufficient experience with such projects, it lacked enough personnel and had up to 80 per cent contract workers at one point. When the decision was taken to change the concept to a partly integrated topside, MHE had already been working for nine months on planning the process equipment. A completely new concept meant that the company had to start all over again, and many working hours were wasted.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 169.

Only 50-60 per cent of the design work was completed in January 1976, and the number of hours was four times higher than the estimate. Mobil resolved to cancel the contract with MHE and brought in a US engineering contractor – Brown & Root – to replace the London-based company on a gradual basis. Mobil regarded Brown & Root as the best qualified candidate for the job, and awarded the contract without competitive tendering.

In October 1975, Brown & Root also took over the contract for planning, management and execution of offshore hook-up work from MHE. It already had the job of technical design and management for work on the loading buoy, flare boom and flowlines.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 156. This meant that the company now held all three of the major assignments for completing Statfjord A.

The factor which caused the biggest problems in planning and building Statfjord A was a massive underestimating of the weights involved.

Bygging av A-dekket,

Bygging av A-dekket,A platform’s weight can be measured in two ways – wet and dry. Wet weight is measured in operating condition with the various process components are filled with liquids. The GBS and topside are designed to cope with a given weight, and the wet weight must not exceed that level. The dry weight is the sum of MSF and equipment alone. A platform is towed out fully or partly outfitted, and the dry weight of the topside must not exceed the tow-out value.[REMOVE]Fotnote: Rolstadås, A., & Norges tekniske høgskole Institutt for verkstedteknikk. (1981). Prosjektstyring. Trondheim: Tapir: 137.

MHE lacked a satisfactory system for either wet or dry weight control. The most accurate possible weight estimates for both MSF and production equipment were already required in early 1975 in order to design the topside. But the wet weight calculations produced by MHE were too low.

Disputes arose between the design company on the one hand and Stord Verft/Aker on the other about the loadbearing capacity of the topside. MHE’s estimate was 34 500 tonnes, while the contract with Stord Verft stipulated 41 500 tonnes. The overall weight ultimately came to 49 500 tonnes. Extensive design work was required to ensure that the MSF could bear this weight. That in turn led to big delays and significantly more expensive fabrication work.[REMOVE]Fotnote: Moe, J. (1980). Kostnadsanalysen norsk kontinentalsokkel : Rapport fra styringsgruppen oppnevnt ved kongelig resolusjon av 16. mars 1979 : Rapporten avgitt til Olje- og energidepartementet 29. april 1980 : 2 : Utbyggingsprosjektene på norsk sokkel (Vol. 2). Oslo: [Olje- og energidepartementet]: 164.

During the fabrication period, MHE’s engineers fell behind with the design work. In an attempt to speed up progress with the technical design, MHE issued incomplete drawings. This meant that the number of drawing revisions and fabrication changes increased. When drawings were amended, structures already installed had to be ripped out and the work done again.

The tow-out or dry weight also caused problems. The loadbearing capacity of the Condeep imposed restrictions on the amount of equipment which could be positioned topside before departure for the field.

It turned out that the maximum tow-out weight was significantly lower than the hardware to be installed. Modules accordingly had to be removed for installation once the platform had been positioned on Statfjord. Such assembly and disassembly, both for this reason and because of revised drawings, had a negative effect on the motivation of the workforce at the Stord yard.

Welders were the largest group of workers involved in fabricating the Statfjord topside. They quickly discovered that welding tankers and oil installations were two different exercises. The former demanded other material types and thicknesses than were used on ships, and the new kind of steel demanded a different welding technique. In addition, the quality of the work had to be improved and its accuracy improved.

Mobil required that all the welders were certified to specified standards. Instead of the earlier approval by Norway’s Det Norske Veritas (DNV), the American ASME norm was introduced. This was divided into six levels, from 1G as the lowest up to 6G. To secure a 6G certificate, a welder had to be able to weld around a pipe positioned at an angle of 45 degrees while welding “through” – in other words, so that the joint is filled.

Many former ship welders failed to pass the tests for the new certificates, and the yard eventually had problems securing sufficient skilled personnel. Since the work was already behind schedule, the management wanted to bring in foreign welders. But this had first to be cleared with the unions. Welders were brought in from other Aker companies to help out. The shortage of welders meant that prefabrication lagged behind, and delays there had a knock-on effect on assembling the topside.

Welds were carefully X-rayed and checked. The yard was told that each weld had to be marked with a number, so that possible faults could be traced directly back to the welder who had done the job. As the work progressed, it became clear that a number of welds had to be redone. If the checks showed more than five per cent error in a weld, it was rejected. A welder who had too many rejects had to be recertified.[REMOVE]Fotnote: Grove, K., Heiret, J., & Stord jern- & metallarbeiderforening. (1996). I stål og olje : Historia om jern- og metallarbeidarane på Stord. Stord: Stord metall- og bygningsarbeider[e]s fagforening: 170. By March 1976, fabrication was far behind schedule.

The pipefitters also found that their work changed with the transition from ships to platforms. There was considerably more pipework and it was more monotonous. The piping was prefabricated and much of the work previously done by the fitters arrived ready-made. Piping was lifted on board from the warehouse by crane.

When ships were still being built, detailed drawings were supplied by the yard’s own engineers, but the individual foreman or fitter could change them if he found it appropriate. That was no longer the case.[REMOVE]Fotnote: Grove, K., Heiret, J., & Stord jern- & metallarbeiderforening. (1996). I stål og olje : Historia om jern- og metallarbeidarane på Stord. Stord: Stord metall- og bygningsarbeider[e]s fagforening: 169. Drawings supplied from London had to be followed to the smallest detail, and all changes had to be reported. The independence and scope of the work was reduced.[REMOVE]Fotnote: Myklebust, A., & Aker Stord A/S. (1994). 75 år på Kjøtteinen : 1919-1994 : Jubileumsbok for Aker Stord. Stord: [Aker Stord].

Working conditions in the workshops were also poor. The worst problem was the heat. The platform steel had to be preheated to 150°C before it could be welded. Although fresh air was blowing into the welding areas to thin out the gases, no effective ventilation was in place. There were smoke and fumes everywhere, while greater use of angle grinders and carbon rod welding increased the noise level.

The Stord Verft workforce noted the transition to the offshore industry directly. Their work became less independent, delivery times were shorter and physical working conditions deteriorated. The many change jobs had an unfavourable impact of their morale, and productivity declined.[REMOVE]Fotnote: Grove, K., Heiret, J., & Stord jern- & metallarbeiderforening. (1996). I stål og olje : Historia om jern- og metallarbeidarane på Stord. Stord: Stord metall- og bygningsarbeider[e]s fagforening:172.

To offset this decline in efficiency, the workforce was expanded to 950 people between June and December 1976. But this did not increase the amount of work actually done.

Designing equipment which was to last “for ever”, and which would never again be seen or accessed, was unusual and challenging. No design codes existed for offshore petroleum projects in 1975. When mechanical engineer Einar Jensen at AOC worked on the rotating machinery, he and his team used design codes developed by Mobil for use on land and DNV codes for shipboard use.

Nobody had ever designed such a large and complex structure as Statfjord A, with all its criss-crossing pipes.[REMOVE]Fotnote: Interview with Eilef Lynghaug, Einar Jensen and Jan-Henry Larsen, former platform managers on Statfjord, by Trude Meland, Norwegian Petroleum Museum, 18 September 2008. To begin with, all the piping was marked. But these marks were subsequently covered with insulation, so the work was wasted.

Bygging av A-dekket,

Bygging av A-dekket,Mobil eventually grasped the seriousness of the position, and realised that tow-out of the platform would have to be postponed for a year. It could not go out to the field before the summer of 1977.

In statements to the media, the company emphasised that more of the work on the installation could thereby be done inshore rather than more expensively and lengthily out on the field:

“The more equipment which can be installed on the platform while it is inshore ¬– according to plans, at Stord, the better. In this way, the time at land can be exploited and difficult and expensive work avoided on the field in the North Sea.”[REMOVE]Fotnote: Stavanger Aftenblad, 13 May 1976. “Størst mulig last en fordel”.

Because of the maximum tow-out weight, however, this plan could not be fully implemented.

Despite the problems, the MSF was eventually completed. This work had taken place in the yard’s dry dock, but the gates were opened on 30 July 1976 and the structure was towed out into the fjord. At the same time, the GBS was on its way from Stavanger to Stord.

The MSF had been built on two redundant tankers – known as Tom and Tina. When the topside was to be mated with the GBS, the latter was ballasted down until it was almost entirely submerged and the two tankers were manoeuvred between the concrete shafts.

Deballasting the storage cells then raised the GBS, so that the topside was carefully positioned on and then lifted by the shafts.[REMOVE]Fotnote: Godø, H. (1980). Plattformutbygging til havs (Vol. Nr 11-1980, Sosialdepartementets sammendragsserie (rapportsammendrag : trykt utg.)). Oslo: Sosialdepartementet: 45. This mating operation took place on 8 August 1976, and work then continued out in Digernessundet.

But the problems were not over. Cracks in the GBS were discovered in 1976 during maximum submersion in connection with the mating operation. They had arisen as a result of excessive temperature fluctuations and a weak section in the concrete. It took two months to repair the damage.[REMOVE]Fotnote: Hanisch, T., Nerheim, G., & Norsk petroleumsforening. (1992). Fra vantro til overmot? (Vol. 1). Oslo: Leseselskapet: 392. Einar Jensen experienced this episode:

“It was a Friday evening, I think, and we were on our way home to Stavanger. When the high-speed ferry berthed, the project manager was standing there and waving us to one side. We went directly to Sola [airport] and into a specially booked plane. Statfjord A was listing. The platform was shipping water in its cells. Four-five of us were involved. There was little drama, but we took in a good deal of water and didn’t know where it was coming from.”[REMOVE]Fotnote: Interview med Einar Jensen by Trude Meland, Norwegian Petroleum Museum, 2 October 2008.

It transpired that there were two cracks, each 20 centimetres long, in the concrete between one “star” cell and a storage cell. The GBS was taking in 15 000 litres of water per hour or 20 buckets a minute.[REMOVE]Fotnote: Stavanger Aftenblad, 14 September 1976. “20 bøtter i minuttet”. But the structure was never in any danger of tipping over or sinking. The pumps installed in the GBS were capable of discharging a million litres per hour, and had no problem controlling the water intrusion. Without the pumps, the GBS would have sunk 60-70 centimetres per day because of the extra displacement caused by the water.

People from AOC and Norwegian Contractors (NC) devoted the weekend to identifying what had happened. When the cracks were located, NC – the company responsible for the concrete structure – injected them with epoxy, a special and elastic form of concrete. Sealing the cracks was a big job, and the incident led to delays. Installing such modules as the living quarters and the helideck had to be postponed until the damage was repaired.[REMOVE]Fotnote: Hanisch, T., Nerheim, G., & Norsk petroleumsforening. (1992). Fra vantro til overmot? (Vol. 1). Oslo: Leseselskapet: 392.

Two months later, Statfjord A listed again while it was lying in Digernessundet. A test of the emergency shutdown procedure for the ballast system went wrong. The living quarters had been installed at one end of the topside, and differing levels of ballast water in the various cells was used to compensate for the added weight. A service operative from the Swedish factory which had delivered the ballast system was going through the procedure for testing the hydraulics. Einar Jensen reports what happened:

“The procedure involved placing each valve in a semi-open position, and then pressing a red button and timing how long it took to shut down. There were 16 cells with ballast water. He tested first one valve and then another. Everything seemed to be working fine. The final stage in the procedure was to place all the valves in a semi-open position and then press the big button. Since we had varying water levels, things began to happen and the platform started to list. The alarms sounded, and the big button fortunately worked. We had a well-qualified man in the control room who pressed the button as soon as he saw the platform begin to list.”[REMOVE]Fotnote: Interview med Einar Jensen by Trude Meland, Norwegian Petroleum Museum, 2 October 2008.

The procedure followed would have been correct for a system which was not in operation. Since the system on Statfjord A was in fact operational, the final stage should have been left out.

This was a serious incident. The platform listed by three degrees, which means that the topside sank by eight-nine metres along one side.[REMOVE]Fotnote: Gjerde, K., Ryggvik, H., & Gooderham, R. (2014). On the edge, under water : Offshore diving in Norway. Stavanger: Wigestrand: 158. It was evacuated, and nobody was hurt. Subsequent reports have alleged that people jumped from the topside, but Jensen denies this:

“People didn’t jump from the topside, but a scaffolding ladder was installed on each side down to a barge on the water. When the platform listed, the stair on one side became far too short, so that when you reached the bottom step the surface was still some way down. It’s possible that some people who went down those stairs jumped, but I can’t confirm it.”[REMOVE]Fotnote: Interview med Einar Jensen by Trude Meland, Norwegian Petroleum Museum, 2 October 2008.

When Mobil decided that the tow-out of Statfjord A should be postponed by a year, a new date was also set – 3 May 1977. That deadline was met, and the platform was in position on the field by 8 May.

Grouting – filling the space between the GBS base and the seabed with gravel – started two days later. The remaining work of completing Statfjord A and readying it for production could then begin. Much work and many challenges were still to come.

Byggestart for A-en, historie, forsidebilde,

Byggestart for A-en, historie, forsidebilde,This initiated a new industry in the Hinnavågen district on the outskirts of Stavanger. It began with the Condeep-type concrete gravity base structure (GBS) ordered by Mobil to support the topside for an oil and gas platform on Britain’s Beryl field. While Beryl A and eventually also Brent A – again for the UK continental shelf – were under construction, work also began on casting the GBSs for Statfjord A and Brent D in the Hinnavågen dry dock.

Building four such massive structures meant that several thousand personnel had to be recruited from all over the place. Norwegians, Swedes, Finns and other nationalities flocked to the construction sites in Stavanger and at Stord further north, where the Statfjord A topside was fabricated and outfitted. But the question was where all these incomer workers to live and how to provide for them.

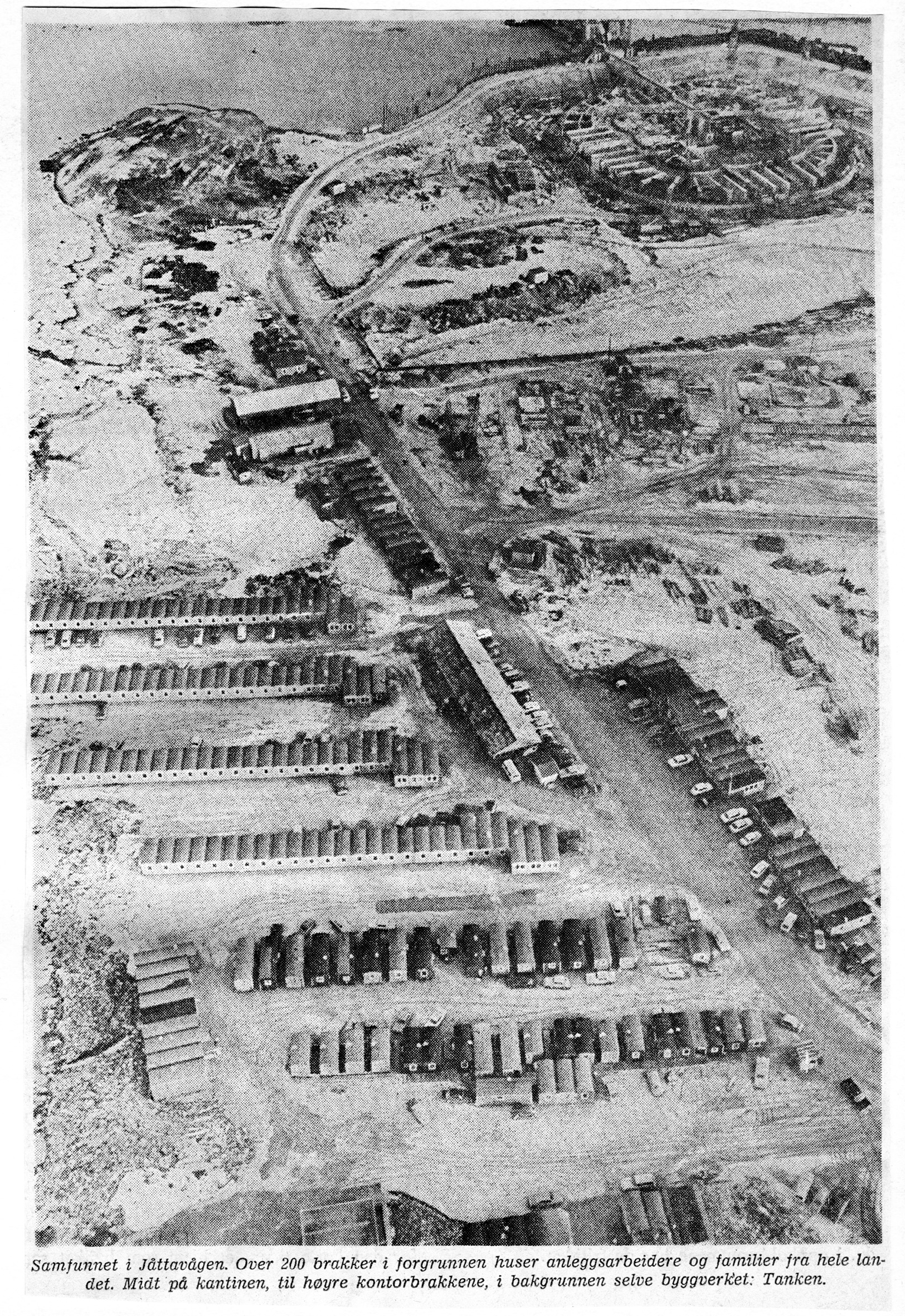

brakkebyene,

brakkebyene,Hinnavågen was a full-bloodied construction site during 1973-77. Not only were four large Condeeps being built in the bay and out in the fjord, but a large work camp had also been established on land to accommodate several thousand incomers. The same phenomenon occurred at Kjøtteinen on Stord, where the Stord Verft yard was located.

Many of the work camp residents in both places were employed on Statfjord A as well as on the other platform structures which lay in the Gands Fjord outside Hinnavågen or Digernessundet off Stord. Workers who could not be accommodated in the camps were packed together on hotel ships berthed at the quays.

During the busiest period between 1974 and 1976, an average of 800 people at a time occupied the temporary accommodation in Stavanger, but few worked there for more than six months. Over the whole period, 3-4 000 people were housed in the work camps and the hotel ships.

The work camp had become twice the size envisaged when construction companies A/S Høyer-Ellefsen and Ing F Selmer A/S applied to the city council for permission to lease the Hinnavågen area in order to “build offshore projects for the oil industry”.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger. A/S Høyer-Ellefsen and Ing F Selmer A/S joined forces with Furuholmen to found the Norwegian Contractors (NC) joint venture, which was responsible for casting the Condeep GBSs.

Together with the Aker group, these two companies had won the order to build and outfit Beryl A as the world’s first concrete production platform. They submitted a request in 1973 to the city council for permission to fill in the Hinnavågen bay in order to create a dry dock, and to use the flat ground behind for warehousing and a work camp.[REMOVE]Fotnote: City of Stavanger, executive board case 1975 A, 7.9. 1972. A/S Høyer-Ellefsen and Ing F Selmer A/S had applied to the council as early as 1972 to lease “the areas with adjacent seabed at Dusavika or Hinnavågen, Stavanger, and moreover anchorage at Hillevåg to build offshore projects for the oil industry“. But NC failed to win contracts at the time and the issue was postponed.

At that time, the companies envisage a maximum requirement of 200 beds.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger: 65. This proved to be a very substantial underestimate. The camp reached its peak occupancy in the spring of 1975, with around 2 000 people temporarily quartered there and on three hotel ships berthed at the Hetland quay.

brakkebyene,

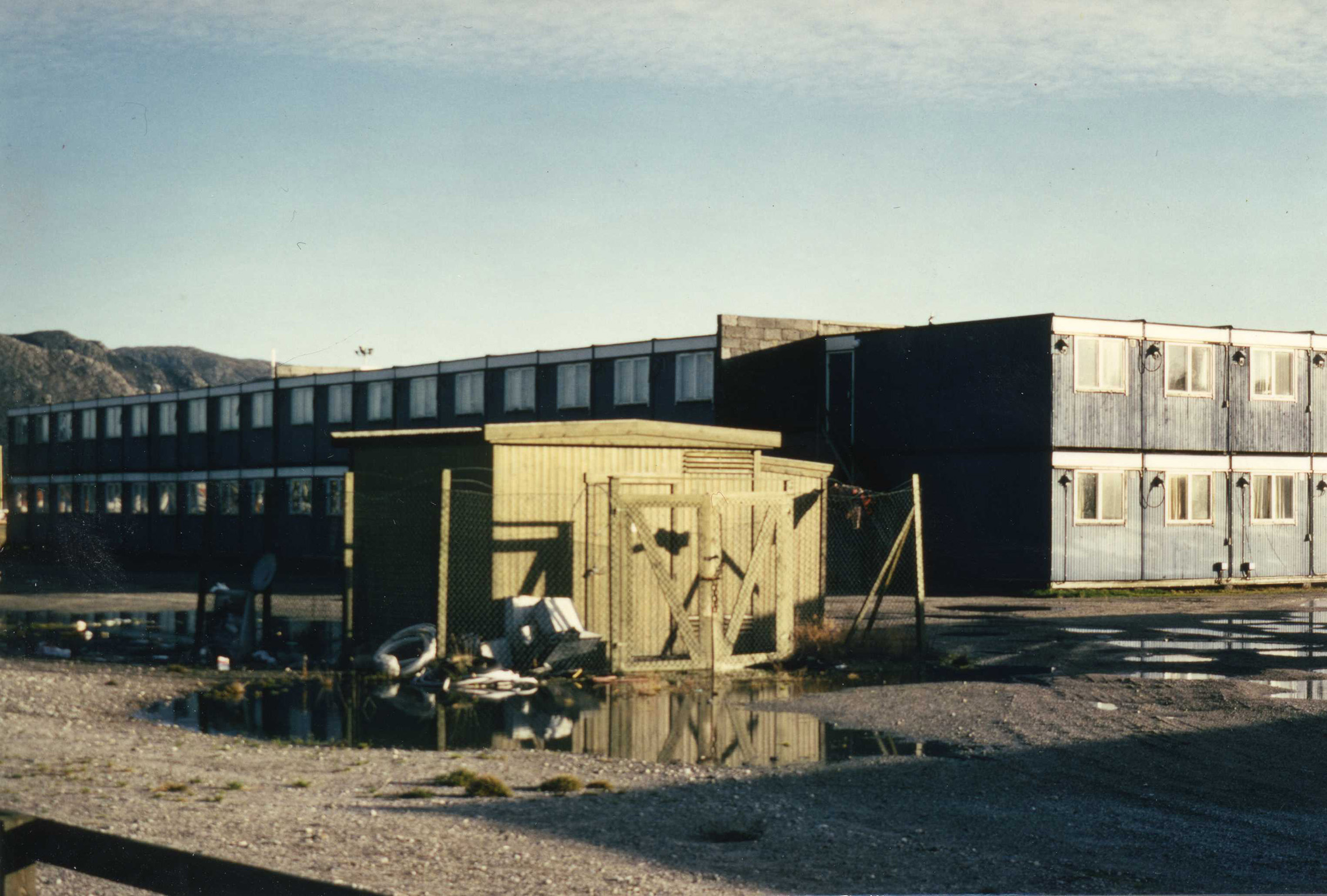

brakkebyene,A year later, the camp had a capacity of 950 people in 60 double – known as “combined rigs” – and single rooms. In addition, all available camping cabins, boarding houses and flats were occupied by incomers working at the facility. Built on former fields and an old rubbish dump overlooking the dry dock in Hinnavågen, the work camp comprised rows of temporary buildings spread around warehouses and temporary offices.

The Ekofisk tank had been cast at nearby Jåttåvågen a few years earlier, again by Høyer-Ellefsen and Ing F Selmer. Part of the area had thereby already been developed, but most of the original site was converted to recreational use after the tank had been completed. The dry dock became a marina. In order to launch new building projects, the whole area had to be redeveloped.

brakkebyene,

brakkebyene,The council’s consideration of the application emphasised the opportunity to secure new industrial jobs for the city. But not everyone was pleased to see Hinnavågen converted into a giant construction site, and residents of Hinna and Jåttå formed an action committee to oppose the scheme.

They were not only negative to the plans, but also wanted certain conditions to be laid down in advance. These related to sewage facilities, Hinna’s Vaulen bathing site and working hours. The council’s executive board responded to certain of these demands.

It instructed the contractors to ensure that all sewage problems in the bay had been overcome by the time the first Condeep base section was ready to be towed out of the dry dock – in other words, within a year. The bathing site had to be retained and protected as well as possible, which meant that the cement mixing plant had to be moved as far to the south as possible. The council also accepted that work would be confined to the hours from 06.00 to 23.00 with exceptions for some jobs – particularly slipforming and repairs.

The action committee also wanted the issue to be postponed and the construction period to be confined to a maximum of two years. These demands were rejected by the council, which gave the contractors a lease for five and a half years and allowed the work to begin immediately.[REMOVE]Fotnote: Stavanger Aftenblad, 6 August 1973. “Uklarhet om spuntveggen”. and Stavanger Aftenblad, 9 August 1973. “Det blir Hinnavågen på visse betingelser”.

In its application to the city council to build temporary accommodation for 200 incomer workers, no account was taken of the fact that the Aker group, which was to perform the mechanical outfitting of the GBS, would also need a large labour force.

Norwegian Contractors (NC), as the GBS construction joint venture was called, was not the only company to accommodate personnel in the work camp. Aker Offshore Contractors (AOC) eventually had a big need to provide sleeping quarters for its own employees as well as sub-contractor personnel.

As the two main contractors, NC and AOC administered the camp jointly but were separately responsible for their own workers. This meant in practice that accommodation varied according to the employer company.

brakkebyene,

brakkebyene,That part of the camp occupied by NC’s personnel was divided into huts with 50 single rooms containing a bed, a cupboard, a desk and two chairs. There was no room for more. Eight hand basins, three showers and two toilets had to be shared. In addition came two day rooms, one at each end of the hut, with TV and armchairs. One of these rooms was supplied with newspapers.

Food was free in the canteen for people working for NC or its sub-contractors, but the steelworkers employed by Aker had to pay for their own meals. They were given a subsistence allowance instead.

In a survey conducted by Per Stangeland at the Rogaland Research institute in 1975-77, perceptions of the food’s quality differed substantially between those who got “free” meals and those receiving an allowance – regardless of the size of the latter.

NC employees were almost unanimously positive to the food and the canteen, while the steelworkers who had to pay were almost equally unanimous in their criticism. Although the two groups each had their own canteen, the food in both was prepared by the same catering company.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger: 170.

But the organisation of meals was not the only employer-related difference. NC personnel had access to a gym, with weights, wall bars, rowing machines, table tennis and a squash court. They also had a ramp they could use to fix their cars.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger: 158. The steelworkers, by contrast, had slot machines in the canteen as their only leisure activity. A kiosk serving the whole camp was open from 12.00 to 22.00.

White-collar workers were treated rather differently. Their hard hats clearly identified them, they had a separate pay system and different accommodation. Most of them resided in boarding houses, and they had their own canteen. One of the huts was also reserved for them, with their own chef and different equipment from in the leisure accommodation for the ordinary workers.

So there was not much to do. A soccer pitch only appeared in 1976. The days were largely spent working, eating and sleeping. Most of the incomers primarily wanted to earn money. TV, cards and reading dominated the evenings. “Work camp syndrome”, a state of lassitude and apathy, is a well-known phenomenon.

brakkebyene,

brakkebyene,Unlike many other construction sites, however, Hinna was only seven-eight kilometres from downtown Stavanger and bus services were good. According to some of the old-timers, this had both negative and positive aspects. The disadvantage was that it could be difficult to organise common activities and the environment in the work camp was therefore not as good as it might have been. Much of the social life was drawn out if it.

But precisely the opportunities to escape from the site through a trip into town could have a positive effect. Restaurants, cinemas and the swimming pool were the most popular destinations. The many Finns at the camp were particularly keen to visit the sauna at the city baths. A sauna was only installed at the camp in 1976.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger: 171-172. Quite a lot of time was spent partying, and the Cobra nightclub became the place to meet in town for the Aker workers.[REMOVE]Fotnote: Interview with Svein Jørpeland by Trude Meland, Norwegian Petroleum Museum.

A number of the incomers lived on hotel ships, which were berthed at the site for two periods – February-June 1975 and October 1975-May 1976. These ferries had steel containers packed together on car and sun decks to serve as cabins. The corridors on either side were only a metre wide, and it was always semi-dark below deck. Each container had two rooms – a bathroom with shower and toilet and a bedroom with two bunks, although they were never occupied by more than one person at a time.

The ships offered a higher standard of accommodation than the work camp, but Stangeland says they were not popular. They were cramped, dark and oppressive. Their stuffiness was emphasised, and the normal work camp huts regarded as heaven by comparison. “This is a really shitty place,” one of the residents complained.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger: 161. Between 100 and 150 cabins on the ferry were also used and were – if possible – even worse.[REMOVE]Fotnote: Stangeland, P., & Baldvinsdottir, A. (1977). Condeep : A platform construction site in Stavanger. Stavanger: 160.

So who were the “inhabitants” of the work camp? Almost half of them were Norwegians, who largely came from other Aker companies or sub-contractors around the country. The remainder were mainly from Sweden and Finland, and had worked for long periods in Norway and Sweden before.

There was no organised import of foreign workers, even though Swedish sub-contractors brought their own personnel with them. As construction proceeded, however, the Swedes were increasingly phased out in favour of Norwegians.[REMOVE]Fotnote: Interview with Svein Jørpeland by Trude Meland, Norwegian Petroleum Museum. Few of these “travelling men” remained in Stavanger after the work was finished. They largely moved on to new construction sites.

Both workplace and work camp were male-dominated. No women worked on the GBS, but about 70 of them had jobs at the facility – 50 in the work camp and 20 on the hotel ships, which can be regarded as an extension of the site.[REMOVE]Fotnote: Leira, A. (1978). Kvinner på en oljearbeidsplass : En undersøkelse ved Condeepanlegget i Stavanger (Vol. Nr 8-1978, Sosialdepartementets sammendragsserie (rapportsammendrag : trykt utg.)). Oslo: Sosialdepartementet: 30.

The great majority of the women worked in service jobs, such as food, waitressing, laundry and cleaning. Some had more specialised posts, including secretaries, bookkeepers and switchboard operators, while a few had supervisory jobs such as canteen manager, cleaning supervisor and head cook. The last of these roles was usually played by men in the canteen kitchens. There were also two female crane drivers.[REMOVE]Fotnote: Leira, A. (1978). Kvinner på en oljearbeidsplass : En undersøkelse ved Condeepanlegget i Stavanger (Vol. Nr 8-1978, Sosialdepartementets sammendragsserie (rapportsammendrag : trykt utg.)). Oslo: Sosialdepartementet: 37.

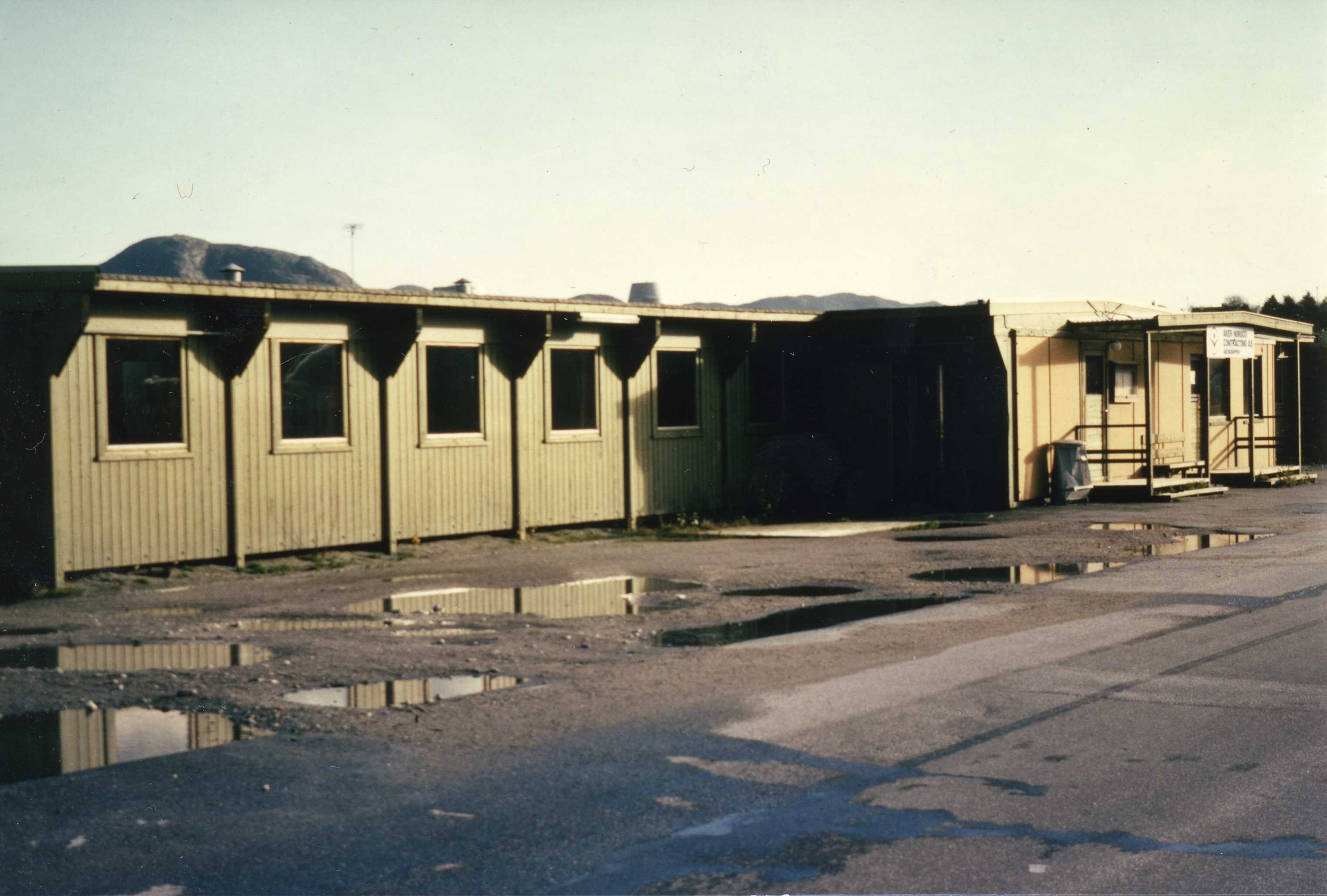

Brakkebyene, a-plattformen,

Brakkebyene, a-plattformen,Fabrication of the steel topside for Statfjord A began at Stord Verft in 1975. Building and outfitting this structure involved a lot of work, so the yard was in great need of additional labour. It was resolved in April 1976 to build temporary quarters for 100 workers at Naustvågen. The number of beds was increased to 450 in September, which again proved far from sufficient.

A number of hotel ships berthed, including North Sea ferry Leda, bought by the yard, as well as Kronprinsesse Märtha, Vikingfjord, Prince of England and Dana Sierena. None of these vessels were regarded positively.

“Work camp capacity was soon exhausted, and the yard had to hire more or less condemned ferries as accommodation,” the workers themselves recalled in the 20th anniversary publication about the union branch at Aker Offshore Partner.[REMOVE]Fotnote: Bedriftsklubben Aker Offshore Partner. (1994). Bedriftsklubben Aker Offshore Partner 20 år : 1974-1994. Stavanger: Klubben: 10. “All the cabins were occupied, including those below the waterline. Ventilation and hygienic conditions were below par and dissatisfaction was great.”

In the spring of 1976, Mobil ordered the company to increase its workforce even further “in an attempt to compensate for the low productivity and slow labour build-up, so that the job could be completed on time and offshore work minimised,” as part I of the Cost Analysis for the Norwegian Continental Shelf (Kostnadsanlysen) put it in 1979.[REMOVE]Fotnote: A total of 2 377 workers and 342 consultants had been hired in to work at the new offshore yard in Kjøtteinen on Stord by 1 January 1977.

The Stord yard had 2 100 registered contract workers in September 1976, and this figure peaked at 2 719 the following January. That meant the population of the local authority had risen by a fifth. A mine site was converted into a work camp, and a small village of caravans also sprang up. Living conditions were wretched. People were packed together wherever space was available.

At one point, this led to a sit-down strike by the workforce. Those who took part were mainly workers hired in from abroad, but included personnel from other Aker companies – particularly Aker Verdal. The action was a protest not only against living conditions but also over working hours, changing room conditions, lack of leisure activities and discrimination against union officials. It was alleged that efforts were made to remove elected officers who called attention to deficiencies, and this was unacceptable to the workforce.

A number of conflicts broke out over working hours. Those who lived furthest away could not afford to go home every third week, because such travel was unpaid. They wanted to work as much as possible and then have a longer period off. The foreign incomers also earned better money and wanted to work more rather than hang around in Stord.

This meant in turn that the permanent workforce also had to work longer hours, which was not popular among those resident in Stord or with the unions. The locals wanted working hours which were better tailored to family life. That sort of thing breeds conflict.

Little provision was made for leisure activities, either in the work camp or in the local Stord community. But something was done. Table tennis, space for playing cards, TV viewing, darts and other activities were initially provided, but the equipment was damaged and both furniture and TVs thrown out of the windows by very inebriated workers, as Knut Grove recounts in his book about Stord Verft.[REMOVE]Fotnote: Grove, K., Heiret, J., & Stord jern- & metallarbeiderforening. (1996). I stål og olje : Historia om jern- og metallarbeidarane på Stord. Stord: Stord metall- og bygningsarbeider[e]s fagforening: 163-164.

This was a period of conflict, with much drunkenness and hullabaloo. But Statfjord A was towed out to the field on 3 May 1977, and Stord Verft had failed to win any new major contract. So the travelling men moved to new construction sites elsewhere. The work camp was already empty by the end of 1976.

Statfjord A was placed on the field in the North Sea by 1977. In Stavanger, NC had won new contracts – starting with Statfjord B and then Statfjord C. Eight other GBSs were to follow. It was not until 1993 that the last of the Condeeps left the construction site at Hinna. But things were never again the same as in 1974-79, when four large concrete structures were being built at the same time and 3 000 people were at work.

Stord, on the other hand, went from thousands of incomers in 1977 to lay-offs and dismissals the following year. The yard had waited for the next big project – Statfjord B – which never came. Read more under the title “The biggest single contract in Norwegian history“