Diving on Statpipe

Statpipe’s first leg ran from Statfjord to Kårstø, where the natural gas liquids (NGL) were separated out. The dry gas was sent back across the Trench to the Draupner S riser platform, where a spur from Heimdal to the north brought additional gas. Statpipe then continued to Ekofisk.

It is no coincidence that the record for total hours spent by divers in saturation on the NCS was set in 1983-85, when work on the pipeline was at its most intensive. This Statpipe diving came in addition to the extensive underwater work being done on Statfjord at the same time.

Despite Statoil being the operator, the many major studies conducted in advance and the pipeline’s status as a national prestige project, most of the contracts went to foreign companies.[REMOVE]Fotnote: Nerheim, 1996: 69. The huge laybarges attracted the greatest media attention, with McDermott’s LB 200 as the most impressive. But a DSV was always to be found just behind – and occasionally ahead – of these vessels. The diving contract was awarded to the Norwegian company Stolt-Nielsen Seaways (SNS). That represented a solid consolation prize for losing out on the main Statfjord assignment. For two years, the company’s DSV Seaway Condor shadowed the pipelaying process. Diving on Statpipe was so extensive that other contractors were also drawn in. The semi-submersible DSV Uncle John, built for Comex by Norway’s Aker group, participated both indirectly via research and verification dives at the Norwegian Underwater Technology Centre (Nutec) and directly in the actual pipelaying. Nevertheless, no single company before or since has been responsible for as many continuous days in saturation on the NCS as SNS during the Statpipe project.

Dykking ved Statpipe,

Dykking ved Statpipe,Seaway Condor had 80-90 people on board at any given time, of whom 35-45 were saturation divers.[REMOVE]Fotnote: Intervju med Einar Wold Svendsen, 30. mai 2006. As a rule, 15 men were in saturation at all times during the work on Statpipe. Inspection accounted for a substantial part of the work. Most diver time in the water was devoted to building up the seabed under and around the pipeline at vulnerable points. Sandbags had to be hauled in some places, while cement was applied elsewhere. A great deal of the diving took place in 190-200 metres of water, which meant that the divers spent up to nine days in decompression. The deepest operational work dive took place in 245 metres on the edge of the Trench off the island of Utsira. This involved measuring the length of a free span, a job which ROVs were still unable to do. Although most of the line pipes were welded together up on the laybarges and laid out in full length, a good deal of welding was required on the seabed.[REMOVE]Fotnote: Intervju med Magne Vågslie, 30. mai 2006. Vågslie var dykkesjef for Stolt om bord på Seaway Condor i den aktuelle perioden. Since sections of the pipeline were laid by different barges from various starting points, they had necessarily to be welded where their ends met. Steps were naturally taken to avoid such a meeting point at the bottom of the Trench. With much thicker pipes and higher pressure in the welding habitat, this work was even more demanding than on Statfjord.

With such a large number of divers involved and an average saturation time of around occasionally combined components from manufacturers in different countries. Divers in Norway viewed systems from Germany’s Dräger as the best, with Italian and British products regarded as of poorer quality. Arctic Surveyor used a Dräger spread with two chambers.[REMOVE]Fotnote: Swann, 2007: 437. Diver comfort on Seaway Falcon improved markedly when it acquired a separate toilet chamber. But this was very expensive to operate because there were entrances from both habitat and decompression chamber.[REMOVE]Fotnote: Intervju med Arne Jentoft, 2. juni 2006. Every time a diver in decompression needed to use the facility, it had to be blown down from the working pressure to the relevant decompression depth. Large quantities of expensive helium could disappear in such a process. The decompression chamber was provided with its own toilet during a conversion in 1979.

Dykking ved Statpipe,

Dykking ved Statpipe,Seaway Condor had four pressure chambers. Of the 15 men usually in saturation, two-three were generally involved in bell-related work and six were under decompression. The remainder were sleeping or relaxing. All the “rooms” or chambers could be sealed off from each other, with separate pressurisation. Divers were usually “blown down” in the toilet chamber, which was also used to enter or leave the bell with various items of equipment. The divers had two chambers at their disposal when they were not down in the bell. One was used for sleeping and the other for recreation and eating. These two chambers were normally pressurised to the same depth, so that the divers could move freely between them. However, the decompression chamber was always separate and only opened when a new team was to start being decompressed. A separate toilet for this chamber avoided the problems which had arisen during the first phase on Seaway Falcon.

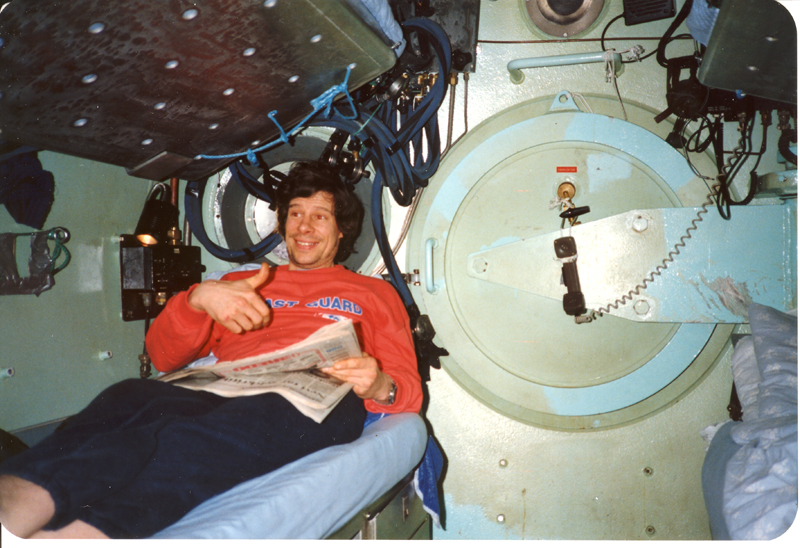

Even though the habitat on Seaway Condor was larger and better than earlier diving spreads, however, life in saturation was never luxurious. To start with, the diving companies used the extra space to increase the number of divers. At the same time, pressurisation in itself imposed a burden on the body. Never before had so many divers spent so long at such depths as they did on Statpipe. Many had big problems sleeping, and a lot also found it difficult to read. One diver reports that he had taken the same book with him from the time he started saturation diving on Statfjord in 1986 until he left in 1992, without succeeding in finishing it. Divers with ambitions of using their “free time” to take various courses or to study often gave up. Light reading was the usual choice. Apart from the stress of the actual working conditions, being packed closely together with a lot of other people and without opportunities to escape could be a source of mental strain.

The most important requirement for a pressure chamber was naturally that it did not leak. Second, the quality of the life support system was crucial for diver comfort and safety. This kept chambers and bell supplied at all times with the right gas mixture and ensured the correct pressure. In addition, it functioned as a form of air conditioning as well as ensuring the appropriate internal temperature and humidity. Striking the right balance between the last two conditions was difficult but also very important for the divers. Particularly when breathing helium gas, it took very little before they began to feel cold. In this area, too, Seaway Condor could avail itself of better and more thoroughly tested technology than the first saturation systems. However, the number of chambers involved and the constant opening and closing of hatches between them made the actual operation of the system more complicated. The large number of hardworking divers also contributed to high levels of humidity. At its worst, these could create a greenhouse for various types of bacteria.

Dykking ved Statpipe,

Dykking ved Statpipe,Operating the diving systems during the Statpipe operation was further complicated by the fact that dive depths could vary substantially. That had been a problem even during stationary diving on Statfjord, where saturation habitats on the surface could be set to 138 metres while the actual work was done 10 metres further down. Dynamic positioning allowed the DSVs to maintain position. Since the waves could be very high at times, the bell had to be positioned a good bit above the seabed to avoid hitting the bottom every time the DSV found itself in the trough of a wave. A diver who worked for four hours or more 10 metres below the pressure he was saturated for needed a certain amount of decompression when his stint was over. The people on the surface who regulated the pressure and calculated this could find it hard to make the right adjustments. During diving on Statpipe, a work team could often be moved to another point along the line at a completely different depth during one and the same saturation period. In some places, moreover, the seabed terrain could be so steep that the divers depended on changing depth in order to do simple jobs. They called this “yo-yo” diving. No tables existed which could give an exact answer to how they should be decompressed in such cases.

Diving on a large scale was also needed where the pipeline came ashore at Kalstø. Norwegian construction contractor Selmer had the contract to build a 600-metre concrete culvert which would protect the pipeline in the rough landfall zone. This was constructed in five sections measuring 80-140 metres long, which were towed to Kalstø.[REMOVE]Fotnote: Statpipe bygges, Infofilm ca 1985. (Statoil). Divers helped to position them. That job was not straightforward, since the underwater terrain at the landfall is uneven. The culvert was accordingly laid on six pillars installed on the seabed. These supports were built by the divers. A big initial job was to clear the seabed with the aid of high-pressure water jets and the like. Their next step was to drill into the bedrock to fix the rebars securely. They then erected the formwork so that the concrete columns could be cast.[REMOVE]Fotnote: Intervju med Geir Egil Skrunes, 25. januar 2006.

Many divers were engaged in this work during 1982-83. The market was more or less swept clean. In many cases, offshore divers took a subsidiary job at Kalstø while on land between tours. During the final phase, the pipeline was pulled through the concrete culvert before being extended to Kårstø. The pipeline became operational on 25 March 1985, when the flare at the processing plant could be lit.