Snorre Tie-in

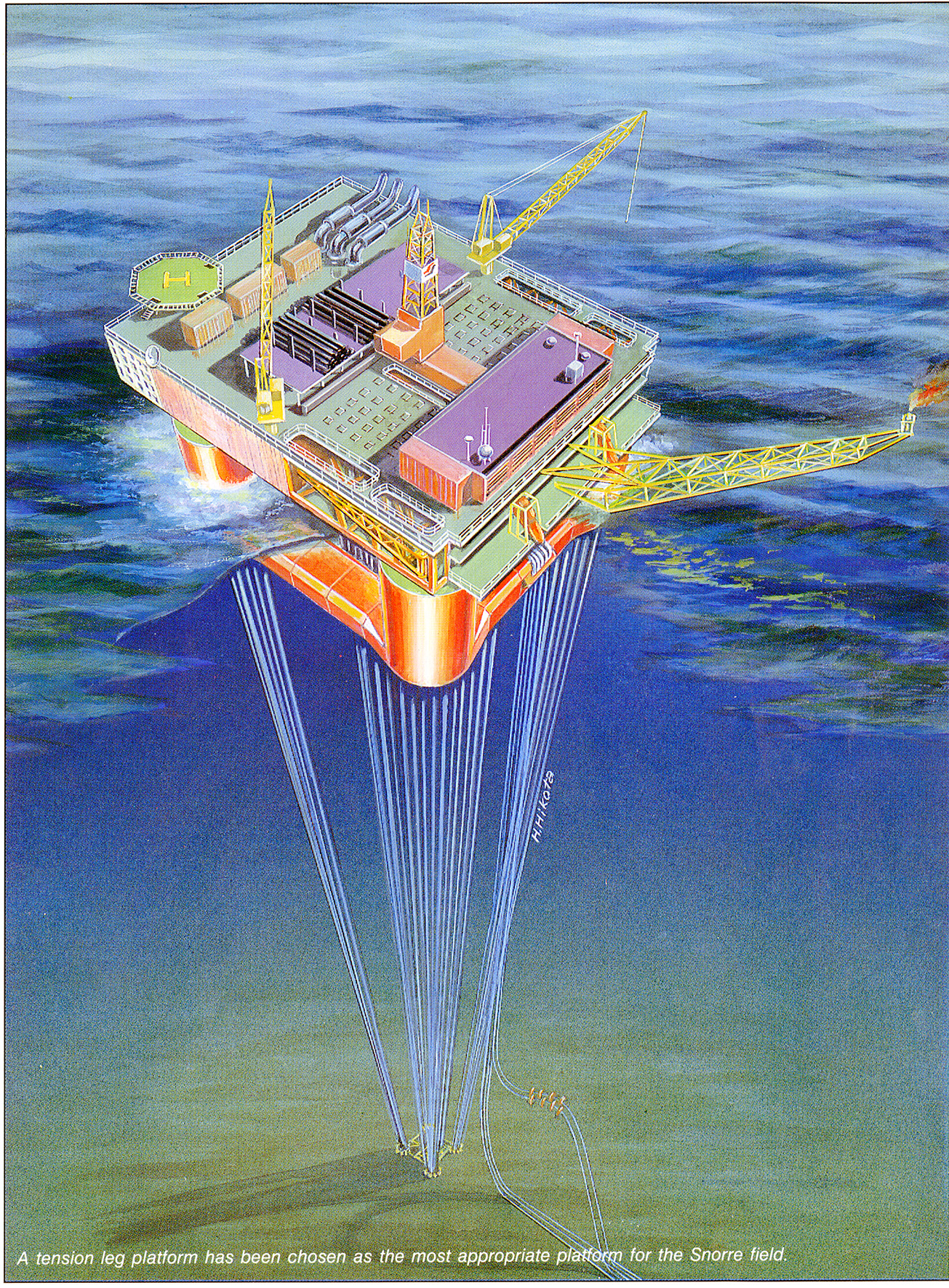

The Snorre licensees resolved in 1987 to develop this North Sea field with a tie-in to Statfjord for final processing, storage and export of the oil. On behalf of the partners in production licences 057 and 089, operator Saga Petroleum submitted a plan for development and operation (PDO) of Snorre to the Ministry of Petroleum and Energy that August. The proposed Snorre A production platform would have process facilities to part-stabilise the oil and gas through pressure and temperature reductions. Associated gas would be sold to the Statfjord group for use as fuel and to replace that field’s own production.

Sources:

Snorre Field Development and Operating Plan , 1987

Lavik, Håkon. Statfjord. The largest oil field in the North Sea . 1997

More about geology and subsea

close

Close

Snorre tie-in

Snorre tie-in Snorre tie-in

Snorre tie-in Snorre tie-in

Snorre tie-in